Every time someone opens a bottle of wine or whisky, they are judging not only the liquid, but also the package that carried it safely to the table.

Most alcohol bottles are made of glass because glass is chemically inert, protects flavor, survives pressure and temperature changes, recycles easily, and supports the premium image people expect from wine, beer, and spirits.

When we look beyond “tradition”, glass is really a technical tool. It resists ethanol, light, and oxygen better than most alternatives, and it still looks and feels like a gift when you put it in someone’s hand.

Is glass’s chemical inertness the key for ethanol and aromas?

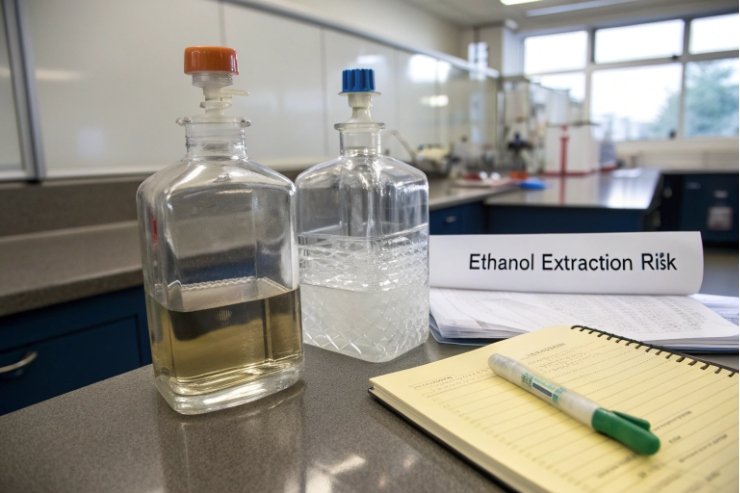

Alcohol is a powerful solvent. If the package is not stable, the spirit slowly starts to extract whatever it can from the wall and the closure.

Yes. Glass is near-inert, non-porous, and has excellent gas and aroma barrier properties, so it does not react with ethanol or steal aroma molecules, which keeps alcohol flavor stable over long storage.

Why ethanol and complex aromas demand an inert container

Spirits, wines, and liqueurs are a mix of ethanol, water, acids, sugars, and hundreds of aroma compounds. Many of these molecules are small, reactive, and sensitive to oxygen and foreign materials. If the container is slightly porous or reactive, two problems appear.

First, aroma scalping 1. Some plastics allow aroma molecules to diffuse into their structure. Over time, top notes fade and alcohol tastes flat. Glass does not do this. Its structure is rigid and non-porous at the molecular level 2, so volatiles stay in the liquid and the headspace, not in the wall.

Second, migration from the container into the product. High-strength ethanol can drive chemical migration from packaging polymers 3. This can change flavor and raise safety questions, especially for long-aged spirits that may sit in bottles for ten or more years. With properly formulated glass, migration from the container wall is essentially zero. The only real migration risks come from the closure system and any decorative layers, which we can manage separately.

Glass is also an excellent barrier to oxygen and water vapor. That matters even for high-alcohol products. Oxygen slowly dulls fruit in wine, changes hop character in beer, and can shift the balance of esters and aldehydes in spirits. With glass, any oxygen pick-up mostly comes through the closure, not the bottle itself, so we can focus on corks, caps, and liners when we tune shelf life.

Finally, glass does not hold smells. If a bottle is washed correctly, it has no “memory” of previous fills. That makes refill and returnable systems cleaner and safer, and it reduces the risk that a delicate gin ends up with a ghost note from the whisky that was in the bottle before.

Do weight and clarity support premium pricing and gifting?

Alcohol is a social product. People open bottles at tables, parties, and celebrations. The package must feel right in the hand in those moments.

Yes. The weight, clarity, and design freedom of glass help alcohol brands signal quality, justify premium prices, and make the bottle feel like a natural choice for gifting and collecting.

How glass turns protection into perceived value

Glass gives designers a wide range of tools that plastics and cartons cannot copy easily. A thick base, a sharp shoulder, or a long, elegant neck is not only an aesthetic choice. It changes how the bottle feels when someone lifts it. Extra glass weight in the base, a deep punt, and clean, sharp edges all tell the hand and eye: this is solid, this is special.

That feeling supports higher price points. When customers compare two bottles on a shelf, they often treat bottle weight as a cue for quality 4, even if they do not say it out loud. For gift buyers, this effect is even stronger. They want the person receiving the bottle to see effort and care before the cork or cap is opened.

Clarity also matters. For wines, spirits, and many liqueurs, color and brilliance are part of the product story. Glass lets people inspect hue, viscosity, and clarity through the wall. A deep amber whisky, a vivid ruby port, or a bright green herbal liqueur all look more appealing behind clean glass than behind a cloudy or opaque material.

At the same time, glass offers a big decoration canvas: embossing, debossing, screen print, metallic foils, spray coatings, and textured finishes. These features let brands anchor their identity in 3D, not just on a label. A custom shoulder shape or embossed crest can become as recognisable as a logo.

Of course, weight has a sustainability cost. Heavy bottles raise transport emissions. Many brands now choose a middle path: they reduce unnecessary weight in areas that do not affect the hand feel, and they keep enough glass in key zones (base, shoulder) to maintain a premium impression. With smart design, it is possible to cut glass mass without losing the “this feels good to pour and to gift” experience that buyers value.

In short, glass gives us a way to connect physical performance with emotional value. It keeps alcohol safe, and it helps the product look and feel worth its price on the shelf and in the gift bag.

Which safety tests ensure pressure and ΔT performance?

Alcohol bottles must survive more than quiet shelf time. They see filling shocks, pallet loads, possible drops, and, for some products, high internal pressure and temperature changes.

Safety tests such as internal pressure (burst), vertical load, impact, and thermal shock (ΔT) are used on glass alcohol bottles to ensure they can handle carbonation, handling, and temperature swings without failing.

How we test bottles so they do not fail in the field

Different alcohol categories place different mechanical demands on bottles. Still wine and spirits are usually filled at ambient pressure and see modest internal loads. Sparkling wines, ciders, and some RTDs carry high carbonation and need much stronger containers.

To cover these cases, suppliers and fillers rely on a set of standard tests:

- Internal pressure (burst) tests: bottles are filled with water and pressurized until they fail. The burst pressure is measured and compared with the required working pressure plus a safety factor, often aligned with ISO 7458 internal pressure resistance 5. For sparkling wine, this confirms that the bottle can handle several bars of CO₂ without risk during storage and transport.

- Vertical top-load tests: a force is applied to the top of the bottle to simulate stacking and capping loads. This checks that the finish and shoulder can carry pallet weights and closure forces without buckling or cracking.

- Impact tests: controlled mechanical hits on the heel or sidewall show how well the bottle handles knocks from conveyors, crates, and handling.

- Thermal shock / ΔT tests: bottles are cycled between hot and cold baths, with controlled temperature differences, to find the maximum ΔT they can tolerate, commonly referenced by ASTM C149 thermal shock resistance 6. This matters for hot-fill applications, rapid chilling, or sudden temperature changes during washing and service.

These tests are often combined with stress inspections using polariscopes. That allows us to see residual thermal stresses from annealing. If stress patterns are too strong or uneven, the bottle may pass a few tests but fail randomly later. By adjusting annealing curves and glass distribution, we can bring stress into a safe range.

For spirits and liqueurs, pressure loads are usually low, but thermal and mechanical loads can still be serious. Bottles may be stored in hot warehouses, chilled in ice buckets, or moved quickly from cold delivery trucks into warm bars. Thermal shock tests ensure that normal bar handling will not produce sudden heel or shoulder cracks.

In all cases, design and testing go hand in hand. A good shape with generous radii at heel and shoulder, plus proper thickness in critical zones, makes it easier to pass these tests without wasting glass. Coatings and careful line handling then keep that strength intact once bottles leave the factory.

Are recycling and refill programs simpler with glass?

Packaging is under pressure to be not only safe and beautiful, but also circular. Many brands now ask how many times a bottle can be reused and how cleanly it can re-enter the material loop.

Yes. Glass can be washed and refilled many times in return systems and then recycled endlessly as cullet, which makes closed-loop programs for alcohol bottles simpler and more credible than most plastic or composite options.

Why glass supports both reuse and true recycling

Glass works very well in both main circular models: refill and recycle.

In refillable schemes, bottles are collected, sorted, and washed before going back to the filler. Glass is ideal here because it:

- Resists caustic or alkaline washing solutions used to remove labels and residues.

- Does not warp or creep under repeated heating and cooling cycles.

- Keeps a hard, smooth surface that is easy to inspect for cracks and chips.

With good design—standardised shapes, sturdy finishes, and scuff-tolerant coatings—the same bottle can make many trips between producer, distributor, and retailer. This spreads the original manufacturing footprint over many fills and can lower total CO₂ per liter compared with single-use alternatives.

When redistribution or damage finally takes a bottle out of the refill loop, it still has value as cullet. Glass can be melted and turned back into new bottles without downgrading. Green, amber, and flint streams can be tuned in the furnace to match color targets. For many wine and spirits producers, this reusable and infinitely recyclable loop 7 is a key part of their sustainability story.

Compared with plastic or foil-lined paper, glass also avoids complex layer separation. There is no need to peel away barrier films or separate polymers. The main complication sits in closures and decoration: painted caps, sleeves, and heavy metallic inks can add some non-glass material to the cullet. But with thoughtful design, those elements can be chosen and applied in ways that do not block recycling.

From a regulatory and consumer-trust angle, glass is also easier to explain. “This is glass; it can be recycled again and again” is a simple message. In many countries, deposit systems for beer, soft drinks, and now sometimes wine already exist. Spirits and liqueurs can piggyback on that infrastructure if they use robust glass formats.

For premium brands, refill can even become a customer experience: keep the beautiful bottle, refill it at the bar, at a shop, or via mail-back. Because glass does not age badly in appearance when treated correctly, it supports this model both technically and emotionally. The customer keeps a nice object, and the brand keeps a permanent place on the shelf or bar cart.

Conclusion

Alcohol and glass fit together so well because glass protects flavor, passes safety tests, recycles cleanly, and still looks like something worth opening and sharing.

Footnotes

-

Evidence and mechanism for aroma compound scalping into packaging materials over time. (↩︎) ↩

-

Explains glass nonporosity and near-zero chemical interaction with packaged beverages. (↩︎) ↩

-

Overview of additive migration risks from polymers into food and beverage matrices. (↩︎) ↩

-

Study showing consumers link heavier glass bottles with higher product quality. (↩︎) ↩

-

Standard summary for internal pressure resistance (burst) test methods for glass containers. (↩︎) ↩

-

Defines the thermal shock resistance test method used for commercial glass bottles and jars. (↩︎) ↩

-

Details why glass is reusable/refillable and infinitely recyclable in circular packaging systems. (↩︎) ↩