Many brands focus solely on silica or alumina, overlooking the critical stabilizer that ensures their packaging survives the harsh realities of the supply chain. Magnesium Oxide is the unsung hero that fine-tunes glass for superior chemical longevity.

Magnesium Oxide (MgO) acts as a potent network stabilizer that significantly enhances the chemical durability of soda-lime glass. Due to its high field strength, the Magnesium ion tightens the glass structure more effectively than Calcium, reducing ion mobility and offering superior resistance to both acidic leaching and alkaline corrosion during caustic washing.

The Strategic Importance of Magnesium in Glass

At FuSenglass, we consider Magnesium Oxide (MgO) to be the "precision instrument" of our batch formulation. While Calcium Oxide (CaO) provides the bulk stabilization required to make glass insoluble, it is the addition of Magnesium—typically introduced via Dolomite 1—that elevates a standard bottle into a high-performance container.

In the competitive world of B2B glass manufacturing, we constantly balance three factors: melting efficiency, forming speed, and chemical durability. Magnesium sits right at the center of this triangle. In soda-lime glass 2, which makes up 90% of the world’s packaging, alkali ions (sodium) are the weak link. They want to escape. If they do, your product pH shifts, sediment forms, and the glass looks weathered.

Magnesium enters the glass network as a "modifier" similar to Calcium, but with a crucial difference. The Magnesium ion (Mg²⁺) is smaller and carries a higher charge density (field strength) than Calcium (Ca²⁺). This allows it to pull the oxygen atoms closer, creating a more compact and rigid atomic structure.

This structural rigidity is not just theoretical; it translates directly to performance. A bottle made with an optimized blend of MgO and CaO will survive more cycles in a caustic bottle washer and resist clouding in humid warehouses far better than a bottle made with limestone (CaO) alone.

Key Functions of Magnesium (MgO) in Glass

| Property | Function in Glass Matrix | Benefit to Brand Owner |

|---|---|---|

| Field Strength | High charge density tightens the silica network. | Reduces the rate at which glass interacts with liquid contents. |

| Chemical Durability | Improves resistance to water and alkalis. | Extends shelf life and maintains bottle clarity/gloss. |

| Liquidus Temp | Lowers the crystallization temperature 3. | Reduces defects (stones) in the glass, ensuring stronger bottles. |

| Viscosity Curve | Slows the "setting rate" slightly compared to pure CaO. | Allows for better distribution of glass in the mold (even wall thickness). |

| Thermal Shock | slightly lowers thermal expansion. | Reduces breakage during pasteurization or hot filling. |

To appreciate why Magnesium is so effective, we must look at the atomic physics occurring inside the furnace and how they persist in the finished bottle.

How does MgO improve chemical durability by strengthening the glass network and reducing leaching?

Durability is ultimately a game of atomic restraint. We use Magnesium to lock down the mobile elements within the glass, preventing them from reacting with the contents.

MgO improves durability because the Mg²⁺ ion possesses a higher ionic field strength than Ca²⁺ or Na⁺. This allows it to bond more strongly with non-bridging oxygens, effectively "clamping" the silicate network shut. This tighter structure physically restricts the diffusion pathways, making it significantly harder for water or acids to leach sodium ions out of the glass surface.

The Physics of Field Strength

In my discussions with glass chemists, we talk about "Field Strength" 4 ($Z/r^2$), where $Z$ is the charge and $r$ is the ionic radius.

-

Sodium (Na⁺): Large radius, low charge. Weak field. It is loose and mobile.

-

Calcium (Ca²⁺): Medium radius, double charge. Stronger field. Stabilizes the network.

-

Magnesium (Mg²⁺): Small radius, double charge. Highest field strength of the common modifiers.

Because the Magnesium ion is physically smaller than Calcium but holds the same double positive charge, it exerts a stronger pull on the surrounding oxygen atoms. It acts like a tighter knot in the net.

Reducing Acidic Leaching (Ion Exchange):

When you put an acidic liquid (like lemon juice or a low-pH toner) in a bottle, Hydrogen ions (H⁺) try to swap places with the Sodium ions (Na⁺) in the glass. This is the primary mechanism of corrosion in acidic conditions.

By introducing MgO, we shrink the interstitial spaces—the "tunnels"—through which the Sodium ions travel. The Magnesium ions clamp the network down so tightly that the Sodium is trapped. If the Sodium cannot move to the surface, the ion exchange cannot happen. The juice stays pure, and the glass stays intact.

Slowing Water Attack (Hydrolysis):

Water attacks glass by hydrating the modifier ions. The strong Mg-O bond is much more resistant to hydration than the Ca-O bond. Therefore, glass containing Magnesium dissolves much more slowly in water than glass containing only Calcium. This is why "Magnesia-Lime" glass is often preferred for pharmaceutical applications where water neutrality is paramount.

Comparative Ionic Properties

| Ion | Ionic Radius (pm) | Charge | Field Strength | Impact on Network Tightness |

|---|---|---|---|---|

| Na⁺ (Sodium) | 102 | +1 | Low | Loosens (Creates pathways for leaching). |

| Ca²⁺ (Calcium) | 100 | +2 | Medium | Stabilizes (Blocks pathways). |

| Mg²⁺ (Magnesium) | 72 | +2 | High | Tightens (Constricts pathways significantly). |

| Al³⁺ (Aluminum) | 54 | +3 | Very High | Rebuilds (Network Intermediate). |

While Magnesium is powerful, it is rarely used alone. It works best as a partner to Calcium. Understanding this partnership is key to optimizing for caustic wash lines.

How does the MgO-to-CaO ratio affect alkali resistance for soda-lime container glass?

In glass chemistry, 1+1 often equals 3. The synergy between Magnesium and Calcium creates a "Mixed Earth Effect" that outperforms either oxide acting alone, particularly in high-pH environments.

A balanced MgO-to-CaO ratio leverages the "Mixed Alkaline Earth Effect," where the presence of two different dissimilar divalent ions hinders their mutual mobility. This structural interference is particularly effective against alkaline attack (caustic washing), where a substitution of 2-4% MgO for CaO preserves surface gloss and minimizes weight loss significantly better than pure limestone-based glass.

The Mixed Alkaline Earth Effect

This is a phenomenon that fascinates material scientists. If you have a glass with 12% CaO and 0% MgO, it has a certain durability. If you replace some of that CaO with MgO (e.g., 10% CaO, 2% MgO), the durability doesn’t just stay the same—it improves.

Why? Because the Calcium and Magnesium ions have different sizes and masses. When they are both present in the glass network, they interfere with each other’s movement. They effectively block each other’s vibration and diffusion paths. It is harder for the attacking chemicals to dislodge a complex, jumbled arrangement of different-sized ions than a uniform array of identical ions.

Why this matters for Alkali Resistance (Washing):

Alkaline attack (NaOH washing) 5 is brutal. It strips the silicate network layer by layer.

-

Pure CaO Glass: The Ca-O bonds are susceptible to breakage by strong alkalis.

-

MgO + CaO Glass: The Mg-O bonds are chemically more resistant to alkaline hydrolysis. Furthermore, the presence of Magnesium makes the surface layer more dense.

At FuSenglass, we advise our clients who run returnable bottling lines (breweries, dairies) to insist on a composition that includes Dolomite (MgO). A bottle with ~2-3% MgO will retain its "brand new" shine for 40-50 wash cycles, whereas a low-magnesium bottle might start showing a "scuff ring" or haze after just 20 cycles. That is a direct impact on the brand’s visual appeal and the lifecycle cost of the fleet.

Optimal Ratios for Application

| Application | Typical CaO % | Typical MgO % | Performance Characteristic |

|---|---|---|---|

| Standard One-Way | 10.0 – 11.0% | 0.5 – 1.0% | Cost-effective. Adequate for single use. |

| Returnable (Washable) | 9.5 – 10.5% | 1.5 – 3.0% | High Alkali Resistance. Resists caustic etching. |

| Pharma (Type II) | 10.0% | 2.0 – 4.0% | High Acid/Water Resistance. Minimizes leaching. |

| Flat Glass (Float) | 8.0 – 9.0% | 3.5 – 4.0% | Optimized for forming and preventing devitrification. |

Chemical durability is useless if you can’t manufacture the bottle without defects. Magnesium plays a massive role in the stability of the production line itself.

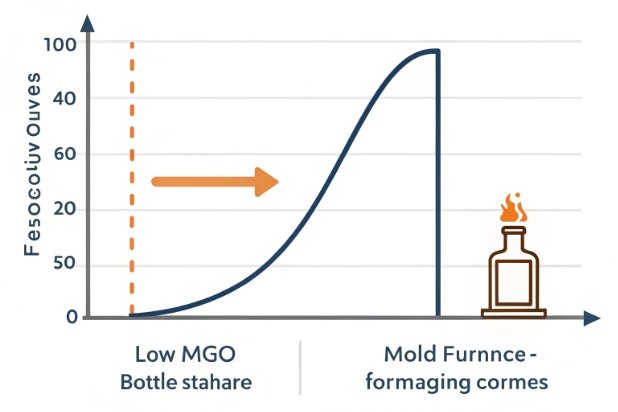

Can higher MgO change production behavior (viscosity, devitrification risk) and indirectly impact durability consistency?

A chemically perfect formula is worthless if it crystallizes in the mold. MgO acts as a crucial process stabilizer, widening the safe working window for manufacturing.

Higher MgO content lowers the "liquidus temperature" of the glass melt, significantly reducing the risk of devitrification (crystallization) during forming. This ensures the glass remains amorphous and defect-free. However, excessive MgO (>5%) can alter the viscosity curve, making the glass "shorter" (setting too fast), which can lead to uneven wall thickness and weak spots in the final container.

Magnesium as a Process Enabler

In the furnace, the enemy is "Devitrification." 6 This is when the molten liquid decides it wants to turn back into a solid crystal (like Wollastonite or Diopside) as it cools. If crystals form, the bottle is ruined—it will be brittle and likely crack.

Calcium Oxide (CaO) has a strong tendency to crystallize. If we try to make a highly durable bottle using only CaO (say 13%), the liquidus temperature spikes. We would have to run the furnace incredibly hot to prevent crystals, which is expensive and dangerous.

Enter Magnesium:

Adding MgO suppresses this crystallization capability. It creates a "eutectic" 7 mixture. By lowering the liquidus temperature, MgO gives us a wider safety margin. We can form the bottle at normal temperatures without worrying that crystals will grow and ruin the glass integrity.

- Consistency: Because the process is more stable, the chemical durability of the finished bottles is more consistent from batch to batch. We don’t have "bad days" where stones or crystals compromise the inner surface.

The Viscosity Trade-off:

However, MgO changes how the glass flows. It tends to make the viscosity curve steeper at lower temperatures.

-

High MgO: The glass sets (freezes) very quickly. This is great for high-speed machines making simple shapes (like beer bottles).

-

Too High MgO: The glass sets too fast. It might not have time to flow into the corners of a complex perfume bottle mold. This results in uneven glass distribution (thin corners), which are physical weak points. A thin corner will corrode or break much faster than a thick one.

Therefore, we limit MgO typically to around 4% max for container glass to maintain that perfect balance of workability and durability.

Production Impact Matrix

| MgO Content | Liquidus Temp (Crystal Risk) | Setting Rate (Viscosity) | Production Consequence |

|---|---|---|---|

| Low (< 0.5%) | High (Risky) | Slower | High risk of devitrification stones; glass is "long" (good for complex shapes). |

| Optimal (1.5 – 3.5%) | Lowest (Safe) | Balanced | Ideal. Good forming speed, low defects, high durability. |

| High (> 5.0%) | Increases again | Very Fast | Glass is "short." Hard to mold complex designs. uneven distribution. |

Finally, as a buyer, how do you verify that your supplier is managing these invisible ingredients correctly?

What tests should B2B buyers use to validate MgO-related durability (ISO chemical resistance, XRF chemistry, and batch-to-batch control)?

You cannot verify magnesium content with the naked eye. To ensure you are receiving a durable, high-performance bottle, you must rely on analytical chemistry and standardized stress tests.

Demand XRF (X-Ray Fluorescence) analysis to confirm the presence of MgO (>1.5%) and verify the CaO/MgO ratio. Validate the performance impact by requiring ISO 695 (Alkali Resistance) and ISO 719 (Hydrolytic Resistance) reports. Regular monitoring of these metrics ensures that the "Mixed Earth" benefit is active and consistent across all production lots.

Validation Protocol for Buyers

When I review quality agreements for our major clients, I ensure they include specific clauses for chemical composition and performance. Here is what you should ask for:

1. The "Recipe" Check (XRF):

Don’t just ask "Is it soda-lime?" Ask for the oxide breakdown.

-

Why: Some manufacturers use cheap limestone (pure CaCO₃) instead of Dolomite (CaCO₃·MgCO₃) to save a few dollars per ton.

-

The Check: Look at the MgO column in the XRF report 8.

-

Standard: > 1.0%

-

High Performance: 2.0% – 3.5%

-

If it is < 0.5%, you are likely getting a straight-limestone glass, which will have inferior alkali resistance.

-

2. The Performance Check (ISO Standards):

Chemistry predicts performance, but tests prove it.

-

ISO 695 9 (Alkali Resistance): This is the most relevant test for Magnesium benefits. It measures weight loss after boiling in caustic soda.

- Requirement: Specify a maximum weight loss per unit area (e.g., < 100 mg/dm²). A glass with good MgO content will consistently show lower weight loss.

-

ISO 719 / USP <660> 10 (Hydrolytic Resistance): This checks for general leaching.

- Requirement: HGB 3 (Hydrolytic Class 3) or better.

3. Homogeneity Check (Density/Seed Count):

Because Dolomite melts differently than Soda Ash, poor batch mixing can lead to "cords" (streaks of different composition).

- The Check: Ask for "Cord" or "Striae" ratings (ASTM C978). High MgO glass that is poorly melted will show visible streaks. These streaks have different durability than the surrounding glass and will erode faster.

Recommended Quality Specs

| Verification Tool | Parameter | Target Range | Why it Matters |

|---|---|---|---|

| XRF Analysis | MgO Content | 1.5% – 4.0% | Confirms Dolomite usage for durability. |

| XRF Analysis | CaO Content | 9.0% – 11.0% | Ensures balanced stabilization. |

| ISO 695 | Alkali Resistance | Class A / Weight Loss < 75mg/dm² | Critical for wash lines / high-pH products. |

| ISO 719 | Water Resistance | Class HGB 3 | Prevents weathering in storage. |

| ASTM C978 | Cord/Striae | Grade C or better | Ensures the MgO is evenly mixed (no weak streaks). |

Conclusion

Magnesium Oxide is not a filler; it is a performance multiplier. By tightening the atomic network and enabling the "Mixed Earth Effect," MgO provides the chemical armor your bottles need to withstand acidic juices, alkaline washes, and humid warehouses. As a buyer, verifying the MgO content is one of the smartest moves you can make to guarantee the longevity and safety of your packaging.

Footnotes

-

A mineral containing both calcium and magnesium carbonate, essential for glass durability. ↩

-

The most common commercial glass, composed of silica, soda, and lime. ↩

-

The temperature at which glass begins to form solid crystals, affecting quality. ↩

-

The electric field strength of an ion, influencing how tightly it binds in the glass structure. ↩

-

Sodium hydroxide solution used for cleaning glass in industrial processes. ↩

-

The process where glass loses its amorphous structure and becomes crystalline, weakening it. ↩

-

A mixture that melts at a lower temperature than any of its individual constituents. ↩

-

X-ray Fluorescence, a technique used to determine the elemental composition of materials. ↩

-

International standard method for testing the alkali resistance of glass surfaces. ↩

-

United States Pharmacopeia standard for testing the hydrolytic resistance of glass containers. ↩