While often confused with "melting point," the softening point is a precise viscosity benchmark that defines how glass behaves during forming and decoration.

The softening point of standard soda-lime glass bottles is approximately 720°C to 740°C. At this temperature, the glass becomes viscous enough to deform under its own weight (viscosity of $10^{7.6}$ poise), marking the upper limit for handling the bottle without it collapsing.

The Viscosity Scale: When Solid Becomes Liquid

At FuSenglass, we view glass not as a solid, but as a supercooled liquid that has become too stiff to flow. The "Softening Point" is a critical marker on this viscosity 1 curve. It is not the temperature at which the glass turns into a puddle (that’s the working point, over 1000°C), but rather the temperature at which the glass loses its structural rigidity.

For a wholesale buyer, the softening point is rarely a limit for filling the bottle (unless you are filling molten metal!), but it is crucial for secondary processing. If you plan to apply ceramic decals (which are fired at high temperatures) or sterilize with extreme dry heat, approaching the softening point can cause the bottle to warp or lose its precise dimensions.

Key Viscosity Checkpoints

| Point | Viscosity (Poise) | Soda-Lime Temp | Practical Meaning |

|---|---|---|---|

| Working Point | $10^4$ | ~ 1040°C | Glass is soft enough to blow into a mold. |

| Softening Point | $10^{7.6}$ | ~ 720°C | Glass deforms under its own weight. |

| Annealing Point | $10^{13}$ | ~ 550°C | Internal stress is relieved in minutes. |

| Strain Point | $10^{14.5}$ | ~ 510°C | Glass acts as a rigid solid below this. |

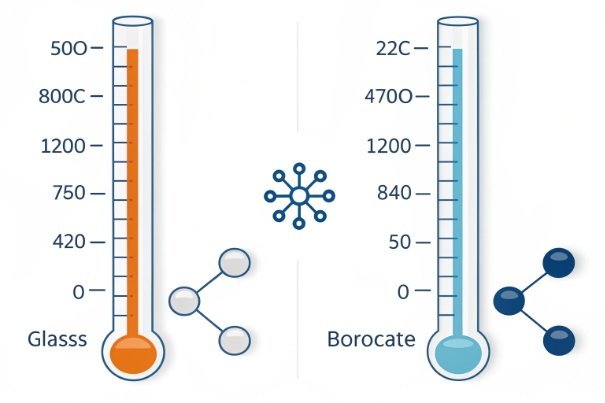

What is the typical softening point range for soda-lime glass bottles versus borosilicate glass bottles?

The chemical backbone of the glass determines how much heat is required to loosen its molecular structure.

Standard Soda-Lime glass bottles (Type III) have a softening point range of 720°C – 740°C. In contrast, Borosilicate glass (Type I) has a much tighter silica network, pushing its softening point significantly higher to approximately 820°C, allowing it to withstand more intense thermal processing.

Material Differences

Why the 100-degree difference? It comes down to "Flux."

-

Soda-Lime: Contains Sodium Oxide 2 ($Na_2O$). Sodium acts as a flux, disrupting the silica network and lowering the temperature at which the glass flows. This makes it cheaper to melt and form, which is why it’s the standard for 90% of bottles.

-

Borosilicate: Uses Boron Oxide 3 ($B_2O_3$) and contains less alkali flux. The network is stronger and requires more energy (heat) to loosen. This high softening point makes borosilicate harder to manufacture but ideal for laboratory conditions where Bunsen burners 4 or high-heat ovens are used.

Comparative Temperature Data

| Glass Type | Softening Point | Annealing Point | Max Continuous Use Temp |

|---|---|---|---|

| Soda-Lime (Type III) | 725°C | 550°C | 450°C |

| Borosilicate 3.3 (Type I) | 820°C | 560°C | 500°C |

| Treated Soda-Lime (Type II) | 725°C | 550°C | 450°C |

How is the glass softening point tested and reported (e.g., ASTM/ISO methods) for bottle-grade glass?

Softening point is not determined by simply watching a bottle melt; it is a precise laboratory measurement of fiber elongation.

The industry standard for measuring softening point is ASTM C338 or ISO 7884-3. In this test, a glass fiber of a specific diameter is suspended in a furnace. The softening point is defined as the temperature at which the fiber elongates at a rate of 1 mm per minute under its own weight.

The Fiber Elongation Method

At FuSenglass, we use this test to monitor the consistency of our raw material batch. If the softening point fluctuates, it means our chemical composition (specifically the alkali ratio) has drifted.

The Procedure:

-

Fiber Pull: We draw a uniform glass fiber from the sample bottle (approx. 0.65mm diameter).

-

Furnace Loading: The top 100mm of the fiber is suspended in a specialized vertical furnace.

-

Heating: The furnace temperature is ramped up at a controlled rate (5°C/min).

-

Observation: We measure the length of the fiber. As the glass reaches viscosity $10^{7.6}$ poise, gravity pulls the fiber down. When the extension speed hits exactly 1mm/min, we record the temperature.

This method ensures that "Softening Point" is a consistent, chemical property of the material, not influenced by the shape or thickness of the bottle itself.

How does softening point relate to real use limits like hot-fill, pasteurization, and thermal shock resistance?

This is the most common misconception in glass buying: High softening point does not mean the bottle won’t break when filled with hot liquid.

The softening point (720°C) is irrelevant to filling processes like pasteurization (85°C) or sterilization (121°C). The limiting factor in these processes is NOT viscosity (softening), but Thermal Shock Resistance (breaking), which is governed by thermal expansion (CTE), not softening point.

The "Melting" vs. "Breaking" Confusion

Buyers often ask, "Can I hot-fill at 95°C? The softening point is 700°C, so it should be fine, right?"

Wrong.

While the glass won’t melt or deform at 95°C, it will likely shatter.

-

Softening Point Relevance: This matters only for high-heat manufacturing steps, such as:

-

Ceramic Decal Firing: We fire decals at 580°C-600°C. This is close to the annealing point 5. If we fire too hot (approaching softening), the heavy bottle neck might start to lean or the bottom might warp.

-

Depyrogenation: Pharma vials are baked at 300°C-350°C to destroy pyrogens. This is safe as it is well below the softening point.

-

-

Thermal Shock Relevance: This matters for filling.

- Soda-lime glass expands rapidly when heated. If you pour 95°C liquid into a 20°C bottle, the expansion stress snaps the glass. The glass is solid (far below softening), but it fails mechanically.

Summary:

-

Deformation Risk: Controlled by Softening Point. (Happens at >600°C).

-

Breakage Risk: Controlled by Thermal Shock ($\Delta T$). (Happens at $\Delta T > 42°C$).

What softening point and thermal-performance specs should wholesale buyers include to avoid deformation during processing and logistics?

Unless you are re-firing the bottles yourself, you rarely need to specify a softening point; your focus should be on the annealing and thermal shock ratings.

Buyers should not specify softening point unless performing secondary high-heat decoration. Instead, specify "ASTM C148 Grade 2 Annealing" to prevent stress warping during storage, and "ASTM C149 Thermal Shock Resistance" to ensure the bottle survives filling and washing cycles.

The Smart Buyer’s Spec Sheet

Over-specifying leads to higher costs. Focus on what affects your line efficiency.

1. For Standard Filling (Beverage/Cosmetic):

-

Ignore Softening Point. It is inherent to the material.

-

Specify: Thermal Shock $\Delta T \ge 42^\circ C$. This ensures the bottle won’t crack when washed or filled.

-

Specify: Annealing Grade $\le 2$. This ensures the bottle doesn’t have "locked-in" stress that could cause spontaneous breakage in the warehouse.

2. For High-Temp Decoration (Screen Printing/Decals):

-

Limit: If you buy blank bottles to print locally, ask for the Annealing Point (typically ~550°C).

-

Instruction: Your decorator must fire the ink below this temperature (or carefully manage the lehr curve) to avoid "slumping" (deformation) of the bottle. If they fire at 650°C, the bottle will deform.

3. For Retort/Autoclave:

- Specify: Headspace Volume. At 121°C, the contents expand. The glass won’t soften, but the pressure will burst it if there isn’t enough room.

Specification Table

| Application | Critical Spec | Why? | Typical Limit |

|---|---|---|---|

| Hot Filling | Thermal Shock ($\Delta T$) | Prevents immediate cracking. | $\ge 42^\circ C$ |

| Decal Firing | Annealing Point | Prevents warping in the kiln. | Process < 580°C |

| Warehouse Storage | Annealing (Polariscope 6) | Prevents spontaneous fracture. | Grade 2 Real Temper |

| Vacuum Capping | Vertical Load | Prevents collapse under top-load. | > 50 kgf |

Conclusion

The softening point of ~720°C is a safety limit for the glassmaker, not the glass user. As a buyer, your primary concern is Thermal Shock. Don’t worry about the bottle melting; worry about it cracking from a sudden temperature change.

Footnotes

-

A measure of a fluid’s resistance to flow, critical in defining glass states. ↩

-

A fluxing agent used in glass manufacturing to lower the melting temperature. ↩

-

A chemical compound that increases the thermal resistance and softening point of glass. ↩

-

A common piece of laboratory equipment that produces a single open gas flame. ↩

-

The specific temperature at which internal stresses in glass are relieved within minutes. ↩

-

An optical instrument used to detect internal stresses in glass materials. ↩