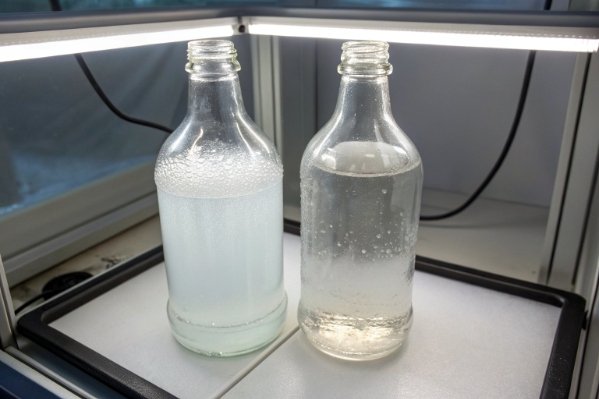

A bottle can look perfect at filling, then turn cloudy after a few harsh washes. That damage looks like “film,” but it is often permanent.

Glass loses alkali resistance when high-pH solutions pull out mobile ions and then attack the silica network, so the formulation decides how fast leaching and etching show up.

What alkali resistance really means in packaging use

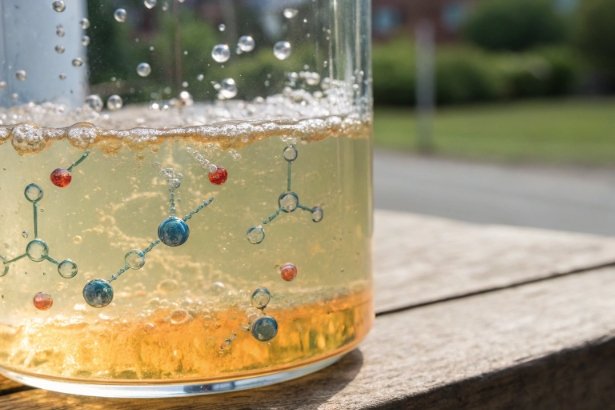

Alkali resistance is the glass surface’s ability to stay smooth, clear, and stable when it meets high-pH liquids. In real packaging, that usually means alkaline washing, CIP 1, dishwasher cycles, and sometimes high-pH products. The surface reaction often starts with ion exchange 2. Sodium and potassium in the glass swap with hydrogen from water. After that, if pH is high enough, hydroxide ions can break Si–O–Si bonds in the network. That second step is where roughness grows fast and haze becomes permanent.

Formulation controls both steps. A tighter network slows ion movement. It also makes it harder for hydroxide to open the structure. That is why higher SiO₂ and Al₂O₃ often improve durability. It is also why higher Na₂O/K₂O can raise risk during hot alkaline washing. The CaO/MgO balance matters too. These oxides can stabilize the network, but the wrong balance can make the surface more vulnerable in long, hot cycles.

In daily production, alkali resistance is not only “chemistry on paper.” It is also how consistent the melt and surface are across batches. A stable recipe with stable raw materials gives stable performance. A drifting recipe or dirty cullet 3 stream can create weak spots that corrode first.

How formulation levers map to field symptoms

| Formulation lever | What changes in the glass network | What the brand sees in use |

|---|---|---|

| Higher SiO₂ | More connected backbone | Slower etching, better clarity retention |

| Higher Al₂O₃ | Lower ion mobility, tighter surface | Less leaching, less haze growth |

| Better CaO/MgO balance | More stable modifiers, better durability window | Fewer “cloudy after wash” complaints |

| Higher Na₂O/K₂O | More mobile ions and open sites | Faster leaching and faster start of etch |

| Better melt quality and fewer defects | Fewer weak initiation points | More consistent results batch to batch |

A buyer can treat alkali resistance like a measurable spec. When the spec is clear, the supplier can tune chemistry and process to match it.

Now let’s break it down into the parts that matter most for purchasing decisions.

Which formulation ingredients most improve alkali resistance (Al2O3, SiO2, MgO/CaO balance), and how do they work?

Alkali corrosion is not random. It follows the easiest path through the glass structure.

SiO₂ builds the backbone, Al₂O₃ tightens and strengthens it, and the right CaO/MgO balance stabilizes the surface so hydroxide has a harder time opening and dissolving the network.

SiO₂: more backbone, fewer weak links

SiO₂ is the main network former 4. In simple terms, more Si–O–Si connections make the structure harder to dissolve. High-pH solutions still can attack silica, but they do it slower when the network is more connected. For packaging, this often means the glass stays glossy longer and resists the “frosted” look after repeated alkaline washing.

Al₂O₃: a practical durability booster

Al₂O₃ is one of the most useful tools for alkali resistance in container-style glasses. It acts like a network stiffener. It reduces ion mobility and makes the hydrated surface layer less porous. That slows leaching. It also reduces the speed of network dissolution at high pH. Many buyers do not see Al₂O₃ on a label, but they see it in performance, especially when bottles face dishwashers or hot caustic lines.

There is a trade-off. Higher Al₂O₃ can raise melting temperature and change forming behavior. If a supplier pushes alumina without process control, defects can rise. Defects then become corrosion start points. So the goal is not “as much alumina as possible.” The goal is “enough alumina for your wash profile, with stable forming quality.”

CaO/MgO balance: stability is not only about “more”

CaO and MgO are often called stabilizers. They can strengthen the network compared with pure alkali modifiers. But balance matters. If the stabilizer mix is off, the surface can still leach and become uneven. An uneven altered layer scatters light and looks hazy, even if the bulk glass is strong.

In real packaging, the best results usually come from a stable recipe window, not a single oxide number. That is why buyers should ask for an oxide target range and a proof test.

Formulation levers and how they work

| Ingredient focus | Main mechanism | Typical benefit | Typical trade-off |

|---|---|---|---|

| Higher SiO₂ | Stronger connected network | Slower etching | Higher melt viscosity 5 |

| Higher Al₂O₃ | Lower ion mobility, tighter surface | Lower leaching, better durability | Tougher melting and forming |

| Optimized CaO/MgO | More stable modifier structure | Less haze growth | Needs good batch control |

This is the core idea: alkali resistance improves when the network is harder to open and when mobile ions are harder to pull out.

How do higher Na2O/K2O levels increase alkali leaching risk during alkaline washing or high-pH products?

Most alkali-resistance failures begin with the easiest ions to remove.

Higher Na₂O/K₂O raises the pool of mobile ions, so alkaline washing pulls more ions out faster, which speeds up surface weakening and makes it easier for hydroxide to start true etching.

Why Na₂O/K₂O are the “first to go”

Na₂O and K₂O help make glass affordable and easy to form. They also create non-bridging oxygen sites 6 in the structure. Those sites are easier for water to penetrate. In high-pH conditions, the surface can lose Na⁺ and K⁺ quickly. That does two important things:

1) It changes the surface composition and creates a hydrated layer.

2) It can raise local alkalinity at the interface, which encourages the next step: network dissolution.

So a glass with higher alkali content can show faster early leaching. In washing systems, that early leaching is a problem because it repeats many times. Each cycle pushes the surface one step closer to visible haze.

Why alkaline washing is harsher than high-pH products

Many high-pH products are not stored hot, and they do not include strong builders or chelators 7. Washing systems often do. Washing also adds agitation, spray impact, repeated wet/dry cycles, and high temperature. These factors can make a moderate recipe difference look huge in the field.

When higher Na₂O/K₂O shows up as haze

Haze can appear from two paths:

-

True etching: micro-roughness that will not clean off.

-

Secondary deposits: silicates or carbonates that look like film but often come from chemistry that started with leaching.

Even when deposits are removed, etched glass stays dull. That is why controlling Na₂O/K₂O is a preventive move, not only a “taste and migration” move.

Risk drivers that multiply the impact of high alkali content

| Driver in use | What it does to the surface | Why higher Na₂O/K₂O makes it worse |

|---|---|---|

| Higher wash pH | Pushes toward network dissolution | More mobile ions, faster start |

| Higher temperature | Speeds diffusion and reaction | Faster leaching per minute |

| Longer dwell time | Allows deeper altered layer | More depletion and roughness |

| Poor rinsing | Leaves alkaline film to keep reacting | Residues keep pulling ions |

| Many cycles | Turns small loss into big haze | Damage accumulates |

In supplier reviews, it helps to link Na₂O/K₂O control to a clear use case. A bottle used once is different from a bottle meant for reuse or aggressive washing. The formula should match the lifecycle.

How do boron-containing glasses compare to soda-lime in alkali resistance for real packaging use?

Some brands ask for borosilicate because they heard it is “more chemical resistant.” That is often true, but the details matter.

Boron-containing glasses, especially borosilicate families, often show better overall chemical durability than soda-lime, but hot concentrated hydroxide can still attack them, so the wash profile decides the real advantage.

Why boron-containing glasses often perform better

Many borosilicate glasses 8 have lower alkali content and a different network structure. The presence of boron can help build a more durable network and reduce ion mobility. In practical terms, that can mean:

-

slower leaching of Na⁺/K⁺,

-

slower haze growth under repeated washing,

-

and better stability in a wide range of products.

This is one reason borosilicate is common in labware and in some high-demand packaging segments.

The important limit: strong hot caustic still attacks

Even durable glasses can be attacked by hot, concentrated hydroxide solutions. In real packaging plants, caustic CIP or bottle washing can be aggressive enough to etch many glasses if exposure is long and hot. So borosilicate is not a free pass. It is more like extra margin.

Real packaging constraints buyers should not ignore

Borosilicate can cost more. It can also behave differently in forming and decoration. Supply chain availability can be different by region. If the brand is selling mass-market beverages, soda-lime glass 9 with a tighter durability window and strong process control can be the better business choice. If the brand needs extreme thermal shock resistance plus chemical durability, borosilicate becomes easier to justify.

In my purchasing discussions, the clean approach is to compare materials using the same wash test and acceptance limits, not by reputation.

Practical comparison for packaging decision-making

| Glass family | Typical strengths | Typical weak points | Best-fit packaging examples |

|---|---|---|---|

| Soda-lime (container glass) | Cost, availability, forming speed | Faster attack in harsh alkali washing | Most beverages, sauces, standard shelf life |

| Boron-containing (borosilicate family) | High chemical durability, thermal shock resistance | Higher cost, may still suffer in hot strong caustic | Premium reuse, thermal cycling, lab-style use |

| Aluminosilicate (specialty) | Strong durability and strength options | Cost and sourcing | Specialty components, high-performance needs |

The best “material upgrade” decision is based on measured performance under your true cleaning or reuse scenario.

What test methods and acceptance criteria should buyers set to verify alkali resistance batch to batch?

A buyer cannot manage what is not measured. Alkali resistance needs a test method and a clear pass line.

Buyers should use a recognized alkali resistance standard for comparability, then add a product-specific wash simulation and batch limits that track drift before haze complaints happen.

Use a standard method first, then simulate real use

A standard method gives a shared language with suppliers. For alkali resistance, ISO-style classification methods use mass loss per surface area after exposure to a boiling alkaline solution for a fixed time. This makes it easier to compare batches and compare factories.

But standard tests do not capture everything about packaging reality. Real washing includes spray impact, drying, detergent builders, and repeated cycles. So it helps to pair the standard method with a simulation that matches your use case, like:

-

a defined CIP exposure (pH, temperature, time, cycles),

-

or an automatic dishwashing cycle test with a defined detergent dose and number of cycles.

Set acceptance criteria that prevent drift

A smart acceptance plan has two layers:

1) A class or limit that defines minimum performance.

2) A tighter internal control limit that triggers action before failure.

For example, if a buyer needs “high resistance,” the contract can require a top class, and the internal spec can require a lower average mass loss to keep safety margin.

What to request from suppliers

For batch-to-batch control, it is not enough to see one report once a year. Buyers should request:

-

a test report from a defined sampling plan,

-

a COA that includes key dimensions and defect checks,

-

and a chemistry control statement (oxide range control and change control).

If the bottle is meant for reuse or harsh washing, it also helps to request a trend chart. A trend chart shows drift early.

Example buyer spec structure

| Control item | What it verifies | Suggested acceptance style |

|---|---|---|

| Standard alkali resistance class | Comparable durability baseline | Meet target class every batch |

| Mass loss internal limit | Early drift control | Mean ≤ internal limit; no outliers over class limit |

| Wash simulation appearance | Real-use haze and etch risk | No permanent haze after X cycles |

| Surface defect KPI | Initiation points for corrosion | Limit stones, cords, heavy scuffs |

| Change control document | Prevent silent recipe shifts | Notify and re-qualify on changes |

A simple acceptance mindset that works

If the bottle will see harsh alkaline washing, choose one clear durability target, then control it with data. When suppliers know the test method 10, sampling plan, and acceptance limits, they can tune the furnace and recipe with confidence. When the buyer only says “must be durable,” the risk stays hidden until the first wave of returns.

Conclusion

Alkali resistance improves when the network is tighter and ions move slower. Control Na₂O/K₂O, tune Al₂O₃ and CaO/MgO, and verify every batch with standard tests plus real wash simulations.

Footnotes

-

Clean-In-Place systems used in manufacturing to clean pipes and vessels without disassembly. ↩

-

A reversible chemical reaction where an ion from a solution is exchanged for a similarly charged ion attached to an immobile solid particle. ↩

-

Recycled broken or waste glass used in glassmaking to reduce energy consumption and raw material usage. ↩

-

Oxides capable of forming a glass network, primarily silica, boron oxide, and phosphorus pentoxide. ↩

-

A measure of a fluid’s resistance to flow; thicker liquids like molten glass have high viscosity. ↩

-

Structural disruptions in the glass network that increase susceptibility to chemical attack. ↩

-

Chemical compounds that bind metal ions, often used in detergents to soften water. ↩

-

A type of glass with high thermal and chemical resistance due to boron oxide content. ↩

-

The most common commercial glass, composed of silica, soda, and lime. ↩

-

International standard method for testing the alkali resistance of glass surfaces. ↩