When bottle quality slips, leaks and breakage hit the winery, not the glass plant. A tight inspection plan keeps corks sealing, screwcaps torquing, and pallets arriving intact.

Inspect wine bottles with a layered system: 100% critical defect vision, finish and capacity measurements, stress checks, and strength tests. The focus is closure fit, base stability, and durability through filling, shipping, and storage.

What does a complete wine-bottle QC plan look like?

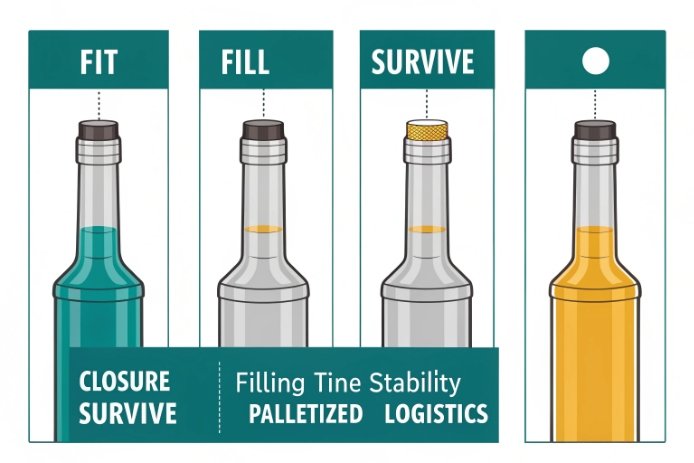

Start with “fit, fill, survive”

A wine bottle is a packaging part, not a decoration. So the inspection plan should match how the bottle fails in real life. Most problems fall into four buckets: closure failure, instability on the line, cosmetic damage that becomes breakage later, and strength failures in transport.

A practical plan uses two layers of control. The first layer is process control at the glass plant: cavity traceability, stable gob weight, stable mold temperatures, and stable coatings. The second layer is product verification: measurements and tests on finished bottles that prove the lot can run on a corker or a Stelvin capper without surprises.

Classify defects so everyone speaks the same language

The fastest way to stop arguments is to define defect severity and the action for each class using Acceptance Quality Limit (AQL) sampling rules 1.

| Defect class | Examples | Risk to winery | Inspection style | Typical rule |

|---|---|---|---|---|

| Critical | cracks, open checks, stones, major blisters, bird swing, broken finish | leak, breakage, safety | 100% vision + reject | AQL = 0 |

| Major | heavy seams, bad finish geometry, base wobble, deep scuffs | line stoppage, high rejects | high sampling + containment | very low AQL |

| Minor | light scuffs, small bubbles not near surface, slight cosmetic haze | appearance complaints | sampling | agreed AQL |

Use traceability to turn defects into fixes

Base codes and cavity numbers should be readable and recorded. When one cavity drifts, fast isolation saves the lot. A winery does not want 10,000 bottles quarantined because one cavity had a worn neck ring.

A short story from the field still sticks in my mind. One customer had “random” cap leaks. The leak rate vanished when bottles from one cavity were removed. The root cause was a small finish ovality drift after a mold repair. That problem only became visible because the inspection report tracked defects by cavity.

Now the deeper questions matter, because closure fit, visual defects, strength testing, and grading rules are the four places buyers win or lose.

If these four areas are locked, mass production becomes calm.

Which dimensions ensure cork and Stelvin sealing and torque?

Leaks feel like a closure problem, but the bottle finish is often the real cause. One millimeter of drift can destroy a cork seal or a screwcap thread.

The key dimensions are finish inner bore, seal land, thread geometry, and roundness. Verify them by gauge and by torque or pull tests on real closures, not only calipers.

For cork: bore, top surface, and insertion geometry

Cork sealing depends on controlled compression and a clean, round mouth. A standard still-wine cork is often around 24 mm diameter (#9 cork). The bottle mouth inner diameter is smaller, often around 18–19 mm at the bore, so the cork compresses and seals. That only works when the bore is round and smooth.

What matters most:

- Bore diameter and roundness (too large or oval = weak seal)

- Top surface flatness (chips or waviness = leak path)

- Mouth finish chips and checks (crack starters during corking)

- Neck alignment (tilt can scrape cork and create channels)

For Stelvin/BVS screwcaps: thread, seal diameter, and support ring

For BVS 30×60 systems, the bottle finish is not “generic.” It is a defined geometry. Typical BVS 30×60 specs include items like thread diameter, seal diameter, and locking ring diameter, each with tight tolerances (for example, thread diameter around 28.3 mm ± 0.3 and seal diameter around 26.1 mm ± 0.3 on common BVS 30×60 guides). The exact numbers should match the agreed finish sheet for the bottle—use a BVS 30×60 finish specification guide 2 as the shared reference.

What matters most:

- Seal diameter and rim quality (liner needs even compression)

- Thread start and thread form (prevents cross-thread and slip)

- Locking ring geometry (controls tamper band behavior)

- Finish ovality (drives torque scatter)

Turn dimensions into acceptance criteria buyers can enforce

Do not stop at “in spec.” Connect dimensions to closure performance.

| Closure system | Dimension to control | Why it matters | Quick functional proof |

|---|---|---|---|

| Cork | bore ID + roundness | controls cork compression | leak test after corking + vacuum/pressure hold |

| Cork | mouth chips/checks | creates leak and crack origin | 100% finish vision + chip gauge |

| Stelvin/BVS | seal diameter + rim flatness | liner seal needs uniform land | torque + leak test after capping |

| Stelvin/BVS | thread diameter + lead | controls application torque and slip | slip/break torque window on real caps |

| Both | finish tilt/ovality | drives sealing scatter | go/no-go gauges + closure trial run |

A purchase spec should name the finish standard (like BVS 30×60 or the agreed cork finish), set measurement methods, and require a short closure trial before full shipment approval.

What visual checks catch seams, checks, and base wobble?

Most defects are visible early if the inspection view is correct. The mistake is checking only “pretty” surfaces and ignoring finish and base details.

Use targeted visual checks: finish and thread, sidewall seams, shoulder and heel checks, and base flatness. Combine high-speed vision with simple manual confirmations like a wobble test and light-line inspection.

Where to look first: finish, heel, and seam line

For wine bottles, the most expensive rejects happen at the winery, not at the glass plant. So visual checks should follow failure risk:

1) Finish and sealing land (chips, checks, dirty rim, malformed thread)

2) Heel and base edge (impact sensitive, crack starts here)

3) Side seam and mold parting line (sharp seams can cut labels and start scratches)

4) Shoulder transitions (thin zones and stress zones)

A good inspection station uses controlled lighting:

- bright-field to see bubbles and stones

- dark-field to highlight surface scratches and checks

- finish cameras angled to catch thread damage

- base cameras for stones, thin heel, and rocker base

Base wobble: simple test, high value

Base wobble looks minor until it jams a conveyor or makes a labeler misplace. Wobble also hints at uneven glass distribution in the heel.

Fast checks that work:

- Rocker test on a flat plate (manual or automated)

- Base ring thickness sampling by cavity

- Punt symmetry check for premium bottles

Make visual inspection actionable with defect maps

The fastest improvement comes when defects are coded by location and cavity.

| Visual defect | What it often means | Where it shows | Fast containment |

|---|---|---|---|

| sharp seam | worn mold or misalignment | vertical line on body | isolate cavity, repair mold edge |

| vertical check | mold too cold or drafts, stress | shoulder/heel | adjust cooling, verify annealing |

| bird swing | unstable gob/shear | random glass string | stop and correct shear timing |

| stones/blisters | melt/refining issue | body or base | quarantine lot, raise refining control |

| base wobble | uneven heel distribution | base edge | adjust bottom plate cooling and timing |

| finish chip/check | handling or neck ring wear | rim/threads | 100% finish sort, fix transfer points |

For buyers, the key is to require finish and base inspection data, not only “body cosmetics.” Those are the two zones that decide sealing and durability.

Which drop and pressure tests validate logistics durability?

A bottle can pass visual inspection and still fail in shipping. Logistics failure is a mix of bottle strength, packaging design, and handling shocks.

Use a test ladder: vertical top load for stacking, internal pressure for sparkling safety, and packaged drop/vibration to validate pallets. The goal is performance with real cartons and dividers, not only bare-bottle tests.

Vertical load: prove stacking and pallet strength

Top load testing checks how the bottle survives stacking forces in pallets and cases. This is critical for heavy bottles and for export routes with long storage.

What to do:

- test bottles from multiple cavities

- include wet conditions if your line sprays water

- set pass limits based on your pallet pattern and layer count

Internal pressure: essential for sparkling and safety margins

Still wine has low internal pressure, but sparkling wine bottles must hold pressure safely. Internal pressure tests aligned to ISO 7458 internal pressure resistance methods 3 prove that the glass distribution and defect control are strong enough.

What to do:

- define pressure ramp method and hold time

- test after thermal conditioning if bottles see warm warehouses

- confirm failure mode (base vs body vs finish) to guide improvements

Packaged drop and vibration: validate the real system

Most breakage happens as a packaging event, not as a bare bottle event. So drop and vibration tests should use:

- real cartons or trays

- real dividers

- real pallet wrap pattern

- real bottle coatings (COF matters for rub damage)

| Test | What it proves | When it matters most | Buyer-friendly acceptance idea |

|---|---|---|---|

| Top load (axial compression) | stacking strength | pallets, warehousing | minimum load with safety factor |

| Internal pressure | safety for sparkling | sparkling lines | pass at target pressure + low scatter |

| Drop (packaged) | shock survival | courier, export, rough routes | no break at defined drop heights |

| Vibration (packaged) | rub and fatigue | long truck/sea routes | low scuff and no breaks after run |

| Leak test (post-closure) | seal integrity | all lines | 0 leaks in defined sample |

If the buyer wants fewer surprises, the best move is to require one “pre-production validation lot” that runs these tests before the first big shipment.

How do color tolerance and glass weight affect grading?

Color and weight decide whether the bottle looks premium and whether it behaves like a premium bottle. They also decide cost, carbon footprint, and break risk.

*Control color with spectro or Lab targets, not only by eye. Control weight by cavity and by minimum strength needs. Grade bottles by how color and mass affect light protection, feel, and logistics cost.**

Color tolerance: protect wine and protect brand identity

For wine, color is not only style. It controls light exposure. Green and amber help reduce light strike risk. Flint is popular for rosé, but it needs better storage control. So grading should include both appearance and performance.

Practical color control steps:

- set a target color family (flint, antique green, dead leaf, amber)

- define tolerance with ΔE or transmission bands based on the CIE Lab* color space 4

- check lot-to-lot consistency, not only average

Glass weight: strength, feel, and shipping trade-offs

Heavy bottles feel premium. They also cost more to ship and can raise break risk in handling if the line is not tuned, because heavier bottles hit harder. Lightweight bottles save cost and carbon, but they need tighter thickness control and better coatings.

A buyer should treat weight as a controlled spec:

- average weight target

- weight tolerance band

- minimum local thickness at heel and shoulder

- cavity-to-cavity scatter limit

A grading model that buyers can use in contracts

Instead of “premium vs standard” by opinion, grade with measurable bands.

| Grading factor | What to measure | Why it changes value | Simple pass rule |

|---|---|---|---|

| Color match | ΔE or transmission band | brand consistency and light protection | within agreed tolerance per lot |

| Color uniformity | streaks, cords visible | looks cheap and signals melt issues | no visible streaking beyond limit |

| Bottle weight | average + cavity scatter | affects shipping and perceived quality | within band, low cavity spread |

| Weight distribution | heel/shoulder thickness | affects breakage and top load | minimum thickness at critical zones |

| Clarity and defects | bubbles, stones, haze | affects premium look and safety | critical defects at AQL 0 |

| Surface condition | scuffs, coating | affects label and break risk | COF stable and low scuff rate |

The best contracts tie color and weight grading to end use. A winery that sells long-aged reds may accept heavier antique green. A fast-turn rosé brand may accept flint and lighter weight but will demand tighter visual and closure performance.

How do audit results and references confirm reliability?

Many buyers stop at price lists and samples. The real test is how the factory runs on a normal day when nobody is watching.

Use audits, trial runs, and customer references to test if a manufacturer keeps promises on quality, delivery, and problem-solving, not just in the first order but over years.

Factory audits: what you should see on the ground

If you can visit, even once, it gives you a clear picture.

Walk through:

- Batch house and raw material storage. Are materials dry, labeled, and tracked?

- Furnace and forehearth area. Is there clear control of temperature and color?

- Forming area. Are operators trained, with clear work instructions at each line?

- Annealing lehrs. Is there recorded temperature control and belt speed logs?

- Cold-end inspection. Do they use 100% automatic vision inspection 5 for critical defects like cracks, blisters, and stones?

- QC lab. Do you see real testing gear for top-load, burst, ΔT, and dimensional checks?

You do not need to be an engineer to spot big issues. Dirty floors, poor lighting, and random piles of pallets are strong early warning signs.

If a visit is not possible, ask for a remote audit with photos, videos, and document review. Many of our overseas clients start this way.

First-article approval and ongoing quality data

Before full production, insist on a first-article inspection (FAI) or PPAP-style package:

- Full dimensional report vs drawing.

- Top-load, burst, and thermal shock (ΔT) testing 6 results.

- Visual defect rate data with AQL levels.

- Polariscope strain inspection 7 pictures for strain.

For mass runs, ask what AQL they use for critical, major, and minor defects. If they can speak about capability in simple terms, it shows they watch trends, not only reject after the fact.

References and reliability history

Finally, ask for references from customers in a similar segment:

- For example, a craft spirits brand if you are launching a new whiskey.

- A cosmetic brand if you buy for skincare.

- A food brand if you pack sauces or honey.

Good questions for references:

- How often do you see quality issues, and how fast are they fixed?

- How is on-time delivery performance?

- How did the manufacturer handle the biggest problem you had together?

Also listen for what they do not say. If a reference hesitates, or refuses to talk about current volumes, there may be a reason.

From our side as a manufacturer, we always invite new clients to start with a smaller project, review the first run together, and only then scale up. That way both sides see how we work under real pressure.

| Evidence type | What it tells you | Warning sign |

|---|---|---|

| Audit report | Process control and housekeeping level | Many open nonconformities, no deadlines |

| FAI / PPAP pack | Real performance vs drawing and specs | Only visual approval, no test data |

| Long-term customer | Stability and problem-solving over years | Only very new or very small references |

Conclusion

Inspect wine bottles by proving closure fit, visual integrity, strength in load and pressure, and stable color and weight. A clear defect class system and cavity traceability make mass production reliable.

Footnotes

-

Sets AQL-based acceptance sampling plans for critical, major, and minor defects. (↩︎) ↩

-

Provides dimensional drawings for the BVS 30×60 bottle mouth used with Stelvin screwcaps. (↩︎) ↩

-

Defines standardized internal-pressure test methods (hold and ramp) for glass containers. (↩︎) ↩

-

Defines CIE Lab* and ΔE calculations for objective color tolerance targets. (↩︎) ↩

-

Shows what 100% bottle vision systems detect and how inline reject works. (↩︎) ↩

-

Standard method for thermal shock resistance testing of commercial glass containers. (↩︎) ↩

-

Explains how polariscopes reveal residual stress patterns that predict breakage and checks. (↩︎) ↩