Frosted bottles scream luxury and sophistication, but does that velvety texture compromise safety? We must uncover if modifying the glass surface weakens its ability to withstand chemical attack from products and washing.

Frosting methods impact durability differently. While acid etching retains the glass’s innate chemical resistance, organic spray coatings are vulnerable to chemical stripping and peeling. Furthermore, the increased surface area of physical frosting (sandblasting) can accelerate surface leaching and trap corrosive residues, creating potential hygiene and stability risks.

The Aesthetic vs. The Atomic: Understanding Frosting

At FuSenglass, the "Frosted" look is our number one request for premium cosmetics and spirits. Clients love the soft-touch feel and the way it diffuses light to hide fill lines. However, a common mistake is treating "Frosting" as a single category. It is not. It is a visual outcome that can be achieved through three radically different chemical or physical processes, each with a unique durability profile.

When we talk about corrosion resistance, we are asking: Will the bottle interact with the liquid inside? and Will the finish survive the environment outside?

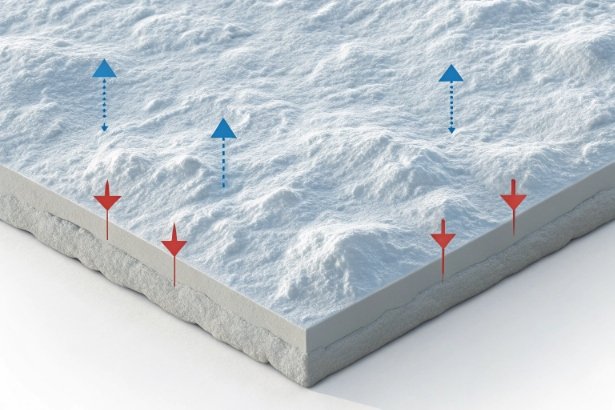

For standard smooth glass, the "fire-polished" skin is the most durable part of the container. It is smooth, sealed, and chemically uniform. When we frost a bottle, we are essentially destroying that skin. We are creating a rough landscape of microscopic peaks and valleys.

From a physics standpoint, this modification changes the rules of engagement.

- Surface Area: Frosting increases the effective surface area 1 of the glass. More surface area means more sites for chemical reaction.

- Porosity: The valleys in the texture can trap liquids, cleaning agents, or oils (fingerprints), which can lead to localized concentration of corrosive agents.

- Material Integrity: Depending on the method, we might be adding a weak material (paint) or inducing stress cracks (sandblasting).

In my experience, 90% of "corrosion" complaints regarding frosted bottles are actually staining or coating failure, not the glass dissolving. Understanding the difference is critical for your quality control.

Frosting Method Overview

| Method | Mechanism | Chemical Nature | Durability Rating |

|---|---|---|---|

| Acid Etching | Chemical immersion (Hydrofluoric Acid). | Subtractive. Removes glass to create texture. | High. (It is still pure glass). |

| Sandblasting | Physical bombardment (Sand/Alumina). | Subtractive. Chips the surface. | Low/Moderate. (Creates micro-cracks). |

| Spray Coating | Application of organic lacquer/paint. | Additive. Layers polymer on top. | Low. (Vulnerable to solvents/scratches). |

| In-Mold Texture | Mold surface pattern. | Forming. Glass cools in rough shape. | Very High. (Fire-polished skin intact). |

To choose the right bottle, you must match the frosting method to the chemical aggressiveness of your product.

Which frosting processes are most likely to affect chemical durability (acid-etched, sandblasted, spray-coated matte, or in-mold texture)?

Not all matte finishes are created equal. Choosing the wrong method for an alcohol-based perfume or an alkaline cleaner can lead to catastrophic packaging failure where the finish peels or stains.

Spray coating is the most chemically vulnerable, as organic paints can peel, blister, or dissolve when exposed to solvents or alkalis. Sandblasting creates deep micro-cracks that weaken structural integrity and trap contaminants. Acid etching offers the highest chemical durability, as it modifies the silica network itself without adding a separate, weak interface layer.

The Hierarchy of Durability

I always advise my clients: If you can afford it, etch it. Here is the technical breakdown of why.

1. Acid Etching (The Gold Standard):

This process involves dipping the bottle into a bath of Hydrofluoric Acid 2 (HF) and Ammonium Fluoride.

- Chemistry: The fluoride eats away the silica and calcium unevenly, leaving a crystalline, matte surface.

- Durability: Once the bottle is rinsed, the surface is pure glass. It has no coating to peel off. It is chemically identical to the original bottle, just rougher. It is fully resistant to alcohol, perfumes, and acidic juices.

2. Spray Coating (The "Impostor"):

This is popular because it’s cheap and eco-friendly (no hazardous HF acid). We spray a water-based or solvent-based epoxy/acrylic lacquer 3 to mimic the frosted look.

- The Risk: It is paint. If your product contains alcohol (perfume) or essential oils, and a drop runs down the side, it can dissolve the paint.

- Corrosion: It’s not glass corrosion; it’s delamination. You will see the "frost" bubble up or peel off like a sunburn.

3. Sandblasting (The Stress Creator):

We blast the bottle with high-speed sand.

- The Risk: This is a physical assault. It creates deep, sharp pits. These pits are "stress concentrators" 4.

- Durability: Physically weak. The bottle breaks easier. Chemically, these deep pits are very hard to clean. Residues get trapped, leading to bacterial growth or cross-contamination.

4. In-Mold Texture (The Durable Illusion):

The mold itself has a rough texture.

- The Reality: This usually looks like "orange peel" rather than a true matte frost. However, it preserves the "fire-polished" skin, making it the most chemically resistant option, though rarely used for premium aesthetics due to the lack of "velvet" feel.

Process Vulnerability Matrix

| Process | Vulnerable To | Failure Mode | Best Application |

|---|---|---|---|

| Acid Etching | Nothing (except HF). | None (Permanent). | High-end Spirits, Cosmetics. |

| Spray Coating | Alcohol, Solvents, Scratching. | Peeling, Blistering, Scratches. | Candle Jars, Single-use colors. |

| Sandblasting | Oils, Dirt, Impact. | Staining (Fingerprints), Breakage. | Arts/Crafts, Limited Run. |

| In-Mold | None. | None. | Mass market, Food jars. |

The texture feels nice, but chemically, it acts like a sponge.

Can frosted micro-roughness increase leaching, haze, or etching when exposed to acids or alkalis?

A rough surface is a giant playground for chemical reactions. By increasing the microscopic surface area, we inadvertently accelerate the interaction between the glass and the liquid it holds.

Yes, micro-roughness significantly increases the effective surface area exposed to the liquid, amplifying the rate of ion exchange (leaching) in acidic products and accelerating dissolution in alkaline environments. Furthermore, the "peaks and valleys" of the frosted topography can trap cleaning agents or product residues, creating localized corrosion cells that lead to permanent staining or haze.

The Surface Area Multiplier

Imagine flattening out the mountains and valleys of a frosted surface. The actual surface area might be 2x or 3x that of a smooth bottle. In chemistry, reaction rate is proportional to surface area.

1. Accelerated Leaching (Acidic/Neutral):

If you put a sensitive pharmaceutical liquid in a frosted bottle (where the inside is frosted—rare, but possible), the leaching of sodium ions will be much faster than in a smooth bottle. This is why we never frost the inside of a bottle intended for liquid storage. The "Fire-Polished" inner surface is mandatory for FDA compliance 5.

- External Issue: If you submerge a frosted bottle in an acid bath (pickling), the matte finish will consume acid faster than smooth glass, potentially altering the texture.

2. The "Fingerprint Effect" (Staining):

This is the most common complaint.

- Mechanism: The valleys of the frost are sized perfectly to trap oils (sebum) from your fingers or drips from the product.

- The "Haze": When oil fills the valleys, it changes the refractive index 6. The "frosted" white look turns "clear" or dark. It looks like a permanent wet spot.

- Corrosion: If that trapped liquid is corrosive (e.g., an alkaline cleaner drip), it sits in that valley and eats away at the glass over days, causing deep pitting that can’t be washed off.

3. Alkali Polishing:

In strong alkaline solutions (pH > 12), the glass dissolves.

- On a smooth bottle, this removes a layer evenly.

- On a frosted bottle, the alkali attacks the "peaks" first because they are exposed on three sides.

- Result: The alkali literally "polishes" the frost away. Your matte bottle starts to look semi-glossy and patchy.

Roughness Impact Table

| Feature | Smooth Glass | Frosted Glass | Consequence |

|---|---|---|---|

| Surface Area | Low (Nominal) | High (200-300%) | Faster reaction rates. |

| Topography | Flat | Peaks & Valleys | Traps dirt/chemicals. |

| Cleaning | Easy (Rinses off) | Difficult (Requires scrubbing) | Residue risk. |

| Oil Interaction | Sits on top | Wicks into pores | Visible "Grease Spotting". |

| Refraction | Transparent | Diffused | Visual changes if wet. |

This brings us to the practical nightmare: cleaning the bottles.

How do dishwasher detergents, CIP alkaline washing, and acidic beverages impact frosted bottles compared with smooth glass?

Industrial washing is brutal on delicate finishes. Your frosted bottle might look pristine on the shelf, but a single pass through a caustic washer can ruin its visual identity.

Alkaline detergents attack the "peaks" of the frosted texture, smoothing them out and causing the bottle to lose its matte opacity (becoming semi-transparent or patchy). While acidic beverages rarely damage the glass structure, the porous frosted surface can trap organic pigments like tannins or dyes, leading to permanent staining that smooth glass would easily repel.

The Washing Challenge

At FuSenglass, we often supply frosted bottles to the beverage industry (e.g., premium vodka). The problem arises when these bottles are returned or washed aggressively.

1. The "Polishing" Effect (Alkaline Wash):

Industrial bottle washers use Caustic Soda 7 (NaOH).

- Chemistry: As mentioned, NaOH dissolves silica. It eats the "mountains" of the frost first.

- Visual Failure: After 5-10 wash cycles, an acid-etched bottle loses its "velvet" look. It becomes shiny, but not in a good way—it looks worn and greasy.

- Spray Coating Failure: If the bottle is spray-coated, the alkali will penetrate the coating, swell it, and strip it off in sheets. Spray-frosted bottles are not dishwasher safe generally.

2. The "Red Wine" Effect (Staining):

If you spill red wine or pomegranate juice on a smooth bottle, you wipe it off.

- On a sandblasted or etched bottle, the pigment molecules get lodged in the micro-fissures.

- Result: The bottle takes on a pinkish hue that cannot be removed without abrasive scrubbing (which further damages the frost).

3. Label Adhesion Issues:

- Labels have a hard time sticking to frosted glass because the adhesive only touches the "peaks" (reduced contact area).

- During washing, water wicks easily under the label through the "valleys," causing labels to peel off much faster than on smooth glass.

4. Mechanical Scuffing:

- Frosted surfaces are abrasive. When frosted bottles rub against each other on a conveyor line (glass-to-glass contact), they act like sandpaper.

- Result: "Scuff rings" appear instantly. On smooth glass, we use coatings to prevent this. On frosted glass, we cannot use those coatings because they would ruin the matte look.

Stressor Response Matrix

| Stressor | Smooth Glass Response | Frosted Glass Response | Operational Advice |

|---|---|---|---|

| Alkaline Detergent | Gradual thinning. | Loss of Matte Finish. | Use neutral detergents; avoid heavy caustic. |

| Red Wine / Dye | Repels. | Absorbs / Stains. | Wipe spills immediately. |

| Conveyor Friction | Coating protects. | Rapid Scuffing. | Use dividers; minimize line pressure. |

| Labeling | Strong bond. | Weak bond. | Use high-tack adhesives (hot melt). |

So, you want the look, but you need the quality. How do you verify it?

What test methods and QC documents should B2B buyers request to prove corrosion resistance after frosting (chemical resistance, abrasion, and thermal cycling)?

Don’t rely on a visual sample. You need data to prove that the frosting won’t peel, stain, or fade.

Mandate the "Cross-Cut Adhesion Test" (ISO 2409) and "Acetone Rub Test" for spray-coated finishes to ensure solvent resistance. For acid-etched glass, require "Stain Resistance" testing (using Methylene Blue or Red Wine) and "Dishwasher Resistance" (EN 12875) to verify the permanence of the texture and ease of cleaning.

The Validation Protocol

When you buy a "Frosted Bottle" from China, the first thing you must ask is: "Is this Etched or Sprayed?" The testing plan diverges based on that answer.

Protocol A: For Spray/Painted Frosting (Organic)

- Adhesion (ISO 2409):

- Cut a grid pattern into the paint. Apply tape. Rip it off.

- Pass: 0% removal (Class 0).

- Chemical Rub Test:

- Rub the surface with a cloth soaked in 95% Ethanol (simulating perfume) or Acetone (simulating harsh solvent) for 50 cycles.

- Pass: No paint comes off on the cloth; no gloss change.

- Scratch Hardness:

- Use a pencil hardness tester 8.

- Pass: > 2H Hardness.

Protocol B: For Acid Etched / Sandblasted (Inorganic)

- Stain Resistance:

- Apply standard staining agents (Olive Oil, Red Wine, Methylene Blue).

- Leave for 24 hours. Wash with warm water and mild soap.

- Pass: No visible stain remaining.

- Dishwasher Simulation (EN 12875):

- Subject bottles to 125 cycles of commercial dishwashing.

- Pass: No significant change in gloss level or translucency.

- Roughness Check (Ra):

- Use a profilometer 9 to measure surface roughness.

- Why: To ensure batch-to-batch consistency of the tactile feel.

Buyer’s QC Checklist

| Test Parameter | Method | Target (Spray) | Target (Etched) |

|---|---|---|---|

| Adhesion | ISO 2409 10 | Class 0 | N/A (Integral) |

| Alcohol Resistance | 50 Rubs (Ethanol) | No Change | No Change |

| Stain Resistance | 24hr Exposure | No Stain | No Stain |

| Scuff Resistance | CAT (Line Simulator) | Moderate | Low (Expect scuffing) |

| Thermal Cycling | ASTM C149 | No Peeling | No Cracking |

Conclusion

Frosted glass balances tactile luxury with technical trade-offs. While Acid Etching remains the champion of chemical durability for high-end packaging, Spray Coating offers versatility at the cost of vulnerability. By understanding the method used and rigorously testing for staining and adhesion, you can ensure your frosted bottle stays as beautiful on the vanity as it was in the showroom.

Footnotes

-

The total area of the surface of a three-dimensional object, crucial for reaction kinetics. ↩

-

A highly corrosive acid capable of dissolving glass, used primarily for etching. ↩

-

Synthetic resins used in paints and coatings, known for weather resistance. ↩

-

A location in an object where stress is significantly higher than the surrounding area. ↩

-

US regulations governing materials that come into contact with food and drugs. ↩

-

A measure of how light propagates through a medium, affecting visual clarity. ↩

-

A strong chemical base used in industrial cleaning, capable of etching glass. ↩

-

A standard test method for determining the hardness of a coating using pencils. ↩

-

An instrument used to measure the surface roughness of a material. ↩

-

Standard test method for assessing the resistance of paint coatings to separation from substrates. ↩