Invisible forces can shatter your production targets. When thermal dynamics are ignored, the very nature of glass turns against you, transforming premium packaging into costly waste.

Yes, thermal expansion causes cracks when it occurs unevenly. Glass is a poor heat conductor, so rapid temperature changes create a "differential expansion" where one part of the bottle expands while another remains rigid, generating fatal tensile stress.

Understanding Thermal Expansion in Glass Packaging

At FuSenglass, I frequently advise clients that glass is a material of paradoxes: incredible compressive strength 1, yet fragile in tension. Thermal expansion 2—the physical tendency of matter to change volume in response to a change in temperature—is not inherently dangerous. If you slowly heat a glass bottle in a kiln from 20°C to 500°C uniformly, it will expand perfectly without breaking.

The danger arises in the real world of high-speed bottling lines. Here, heat is rarely applied uniformly. A hot fill nozzle touches a cold neck; a bottle sits on a cold conveyor while hot liquid fills the body. This creates a battle within the molecular structure of the glass.

The Physics of the Failure

The Coefficient of Thermal Expansion 3 (CTE) for standard soda-lime glass (which we use for 95% of beverage and food containers) is approximately 9.0 x 10⁻⁶ K⁻¹. While this number seems small, the stress it generates is massive.

When a specific region of the glass heats up, it tries to occupy more space. If the surrounding glass is cold, it refuses to yield. The heated glass pushes (compression), but the cooler glass is pulled apart (tension). Since glass is about 10-15 times weaker in tension than compression, the crack invariably starts in the cooler zone that is being "stretched" by the expanding hot zone.

The Business Impact

Ignoring these thermodynamics doesn’t just break a few bottles; it contaminates your filling line with shards, necessitating a complete shutdown for cleanup. For our clients exporting to North America and Europe, we emphasize that "thermal stability" is as much a quality metric as clarity or volume.

| Material Type | Expansion Coefficient (CTE) | Thermal Risk Level | Typical Application |

|---|---|---|---|

| Soda-Lime Glass | ~9.0 x 10⁻⁶ /K | High | Most Food/Bev/Cosmetics |

| Borosilicate (3.3) | ~3.3 x 10⁻⁶ /K | Low | Laboratory, Premium Bakeware |

| Treated Soda-Lime | ~9.0 x 10⁻⁶ /K | Medium | Surface treated for scratch resistance |

Understanding this fundamental behavior is the first step to engineering a robust process.

How does uneven heating create internal stress that leads to cracks in glass bottles?

Uniformity is the shield against breakage. When heat transfer is asymmetric, internal mechanical forces rise rapidly until the material’s elastic limit is breached.

Uneven heating creates a "stress gradient." The expanding hot layers exert compressive force, while the resisting cold layers are forced into tension. Once this tensile stress exceeds the glass’s critical limit (approx. 40-50 MPa), a fracture initiates instantly.

The Tug-of-War Inside the Wall

Imagine a thick glass wall. If you pour boiling water inside, the inner surface tries to expand immediately. However, glass has low thermal conductivity 4 (unlike metal). The heat takes time to travel to the outer surface.

-

Inner Surface: Hot -> Expands -> Under Compression (Safe).

-

Outer Surface: Cold -> Static -> Under Tension (Danger).

The outer surface is being ripped apart by the expanding interior. This is why, when you pour hot water into a cold jar, the outside cracks. Conversely, if you plunge a hot bottle into cold water (thermal shock 5), the outside cools and contracts while the inside remains hot and expanded. The outer surface tries to shrink, placing it in tension.

Transient Stress vs. Permanent Stress

It is important to distinguish between "transient thermal stress" (which disappears once the temperature equalizes) and permanent stress. Transient stress is the killer in filling lines. It spikes in milliseconds. At FuSenglass, we use Finite Element Analysis 6 (FEA) to model these heat flows. We see that the stress peaks not when the bottle is hottest, but during the steepest gradient—usually 2 to 5 seconds after contact with the heat source.

Factors Amplifying the Stress

-

Thickness of the Glass: Thicker glass creates a larger temperature difference (ΔT) between the two surfaces because heat takes longer to travel through. Surprisingly, thicker bottles can be more prone to thermal shock than thin ones if the heating is rapid.

-

Rate of Heat Transfer: Water transfers heat 25x faster than air. A hot water spray creates far more stress than a hot air tunnel at the same temperature.

| Stress Type | Condition | Stress State (Surface) | Failure Mode |

|---|---|---|---|

| Hot Liquid Fill | Inner hot, Outer cold | Outer surface in Tension | Vertical cracks start on outside. |

| Cold Spray (Pasteurization) | Outer cold, Inner hot | Outer surface in Tension | Crazing or checking on surface. |

| Base Contact | Hot body, Cold bottom | Base perimeter in Shear | Bottom separates (circumferential). |

Which bottle areas (finish, shoulder, base) are most sensitive to thermal expansion stress and why?

Not all glass is created equal. Geometry dictates where stress concentrates, making specific zones the "Achilles’ heel" of your packaging.

The Base and the "Knuckle" (Heel) are the most sensitive due to thickness variations and baffle marks. The Shoulder is the secondary risk zone due to complex curvature changes that concentrate mechanical forces.

The Base: The Primary Failure Point

In my experience analyzing broken samples from clients, 70% of thermal failures occur at the base.

-

Thickness: The base is naturally thicker to provide stability and weight. This thickness means the thermal gradient 7 (difference between inside/outside temp) is highest here.

-

Baffle Marks: The mold seam where the bottom plate meets the body mold (the baffle line) acts as a microscopic stress concentrator 8.

-

Contact: The base is in contact with the conveyor belt. If the bottle is hot (90°C) and the conveyor is cold steel (20°C), the base undergoes massive "contact shock" locally, while the body does not.

The Finish (Neck): The Precision Risk

The finish is complex because of the threads and the sealing surface.

-

Capping Stress: If a bottle is hot-filled, the glass expands. If a metal cap is applied immediately, the glass and metal cool at different rates. The neck can be "strangled" by the cap if not properly torqued, or the threads can shear off.

-

Thermal Mass: The neck is often thicker than the shoulder but thinner than the base. This mismatched thermal mass can cause "neck checking" (small hairline cracks) during rapid cooling.

The Shoulder: The Geometric Stress Riser

The shoulder represents a transition from the wide body to the narrow neck. In physics, any change in geometry concentrates stress.

-

Sharp Shoulders: A square-shouldered bottle (like some spirits bottles) traps stress in the corners.

-

Sloped Shoulders: A gentle slope allows stress to distribute more evenly.

At FuSenglass, we advise clients that if they need high thermal resilience (e.g., for autoclaving), they must opt for rounded shoulders over sharp, angular designs.

| Bottle Zone | Risk Factor | Physics Mechanism | Design Mitigation |

|---|---|---|---|

| Base / Heel | High Thickness | High ΔT through wall; slow equalization. | Uniform bottom plate; large heel radius. |

| Sidewall | Uneven Distribution | "Wedging" effects if thickness varies. | 100% wall thickness inspection. |

| Shoulder | Geometry Change | Stress concentration at angles. | Gentle, continuous curves (Campanulate). |

| Finish | Mechanical Interaction | Compression from caps + thermal shock. | Reinforced finish design. |

How do annealing quality and residual stress levels determine whether thermal expansion becomes a cracking risk?

A bottle with hidden internal tension is a ticking time bomb. Thermal expansion acts as the trigger, but poor annealing loads the gun.

Poor annealing leaves "residual stress" in the glass matrix. When thermal expansion adds new temporary stress, the two forces sum up. If the total exceeds the tensile strength, the bottle shatters. Proper annealing resets the stress baseline to near zero.

The Role of the Lehr (Annealing Oven)

After a glass bottle is blown, it is red hot. If it cools naturally in air, the outside hardens while the inside is still soft. As the inside eventually cools and contracts, it pulls on the already-hard outer shell, locking in permanent tension. This is a "strained" bottle.

To prevent this, we pass every bottle through an Annealing Lehr 9. This oven holds the glass at approx 560°C (the annealing point) to relieve all internal stress, then cools it slowly.

The "Sum of Forces" Equation

Think of the glass having a "stress budget."

-

Tensile Strength of Glass: ~40-50 MPa.

-

Residual Stress (Poor Annealing): Could be 20 MPa.

-

Thermal Expansion Stress (Hot Fill): Adds 30 MPa.

-

Scenario A (Bad Annealing): 20 MPa (Residual) + 30 MPa (Thermal) = 50 MPa. RESULT: CRACK.

-

Scenario B (Good Annealing): 2 MPa (Residual) + 30 MPa (Thermal) = 32 MPa. RESULT: SAFE.

This is why two bottles that look identical can behave differently. One survives the filler; the other explodes.

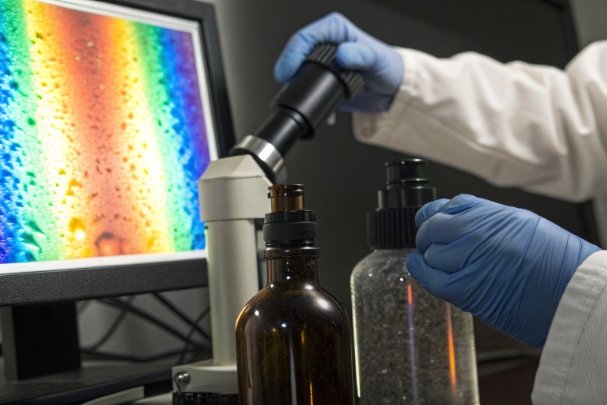

Quality Control: The Polariscope

We categorize annealing quality using a Polariscope 10, which uses polarized light to make stress visible as colored fringes.

-

Grade 1-2: Excellent. Commercial standard.

-

Grade 3: Acceptable for general use, risky for thermal.

-

Grade 4-5: Reject. Will likely break spontaneously or under minor load.

| Annealing Grade | Residual Stress Level | Thermal Shock Resistance | Recommended Use |

|---|---|---|---|

| Grade 1 (Perfect) | Near Zero | Maximum (ΔT ~50°C) | Hot Fill, Pasteurization, Carbonation. |

| Grade 3 (Standard) | Moderate | Moderate (ΔT ~40°C) | Ambient Fill, Wine, Spirits. |

| Grade 5 (Poor) | High | Very Low (ΔT <20°C) | REJECT / SCRAP |

At FuSenglass, our QC protocol mandates that any batch exceeding Grade 2 is flagged for re-annealing or scrapping.

What process controls (preheating, ramp rate, cooling curve) best prevent thermal-expansion cracking in hot-fill and sterilization?

Engineering the environment is just as critical as engineering the bottle. You must guide the glass through temperature changes gently, avoiding the "shock cliffs."

The key controls are a staged "Ramp-Up" and "Cool-Down" where no single step exceeds a ΔT of 35-40°C. Tunnel pasteurizers must strictly monitor spray nozzle temperatures to ensure gradual transitions.

The Preheating Imperative

Never hot-fill a cold bottle. If your product is 90°C and your warehouse is 10°C, the ΔT is 80°C—certain death for soda-lime glass.

- Solution: Use a warm water rinse or steam flush immediately before the filler. Target a bottle temperature of 50°C-60°C. This reduces the shock of the 90°C liquid to a manageable ΔT of 30°C-40°C.

The Tunnel Pasteurization Curve

For products pasteurized in the bottle (like beer or sauces), the bottle travels through a tunnel with multiple spray zones.

-

Zone 1 (Pre-heat): 35°C

-

Zone 2 (Soak): 50°C

-

Zone 3 (Super-heat/Kill): 65°C

-

Zone 4 (Pre-cool): 45°C

-

Zone 5 (Cool): 25°C

The dangerous zones are usually the Cooling zones. Heating is often survived because the outside is in compression (safe). Cooling puts the outside in tension (unsafe). Therefore, the "Cool-Down" ramp must be gentler than the "Heat-Up" ramp.

Conveyor Management

Often overlooked is the bottom contact.

-

Problem: Hot bottles exiting a tunnel (60°C) transfer onto a packing table made of cold stainless steel (20°C).

-

Result: Thermal shock at the base.

-

Control: Use plastic conveyor belts (Intralox) which conduct heat poorly, or pre-heat the metal transfer plates.

Monitoring Tools

Modern lines use "Data Loggers"—electronic dummy bottles that travel through the line recording the exact temperature profile. We recommend running a logger once per shift to verify that a clogged nozzle hasn’t created a cold spot that will shock the hot bottles.

| Process Stage | Critical Control Point | Max Safe ΔT | Action if Limit Exceeded |

|---|---|---|---|

| Bottle Infeed | Pre-heat / Rinse | 42°C | Increase rinse water temp. |

| Filling | Fill Temp vs. Glass Temp | 42°C | Stop line; pre-warm bottles. |

| Pasteurization | Heating Ramp Rate | ~30°C per zone | Check spray nozzles for blockages. |

| Cooling Tunnel | Cooling Ramp Rate | 30°C (CRITICAL) | Slow down conveyor; warm the cooling water. |

| Discharge | Conveyor Material | N/A | Switch to plastic belts or warm mats. |

Conclusion

Thermal expansion is a force of nature, but it can be tamed. By ensuring Grade 1-2 annealing, designing bottles with uniform walls and generous curves, and strictly controlling your filling line’s ΔT to never exceed 42°C, you can virtually eliminate thermal breakage.

Footnotes

-

The capacity of a material to withstand loads tending to reduce size. ↩

-

The tendency of matter to change in volume in response to a change in temperature. ↩

-

A measure of how much a material expands per degree of temperature change. ↩

-

The property of a material to conduct heat; glass has very low conductivity. ↩

-

Stress caused by rapid temperature changes, potentially causing glass fracture. ↩

-

A computerized method for predicting how a product reacts to real-world forces. ↩

-

The physical quantity describing the direction and rate of temperature change. ↩

-

A location in an object where the stress is significantly greater than the surrounding area. ↩

-

A specialized oven used in glass manufacturing to anneal and cool bottles under controlled conditions. ↩

-

An optical instrument used to detect internal stresses in glass and other transparent materials. ↩