Applying an internal layer to glass promises superior chemical inertness and "glide" for viscous products, but it adds a new variable to the thermal equation. A coating that fails under heat turns a premium solution into a contamination risk.

No, internal coatings do not increase the glass’s inherent thermal shock resistance (the ability to withstand sudden temperature changes). In fact, they introduce a failure risk: if the coating’s expansion rate mismatches the glass, high heat can cause blistering, delamination, or particle shedding into the product.

The Role of Internal Coatings

At FuSenglass, we typically apply internal treatments—specifically Siliconization or Ammonium Sulfate Treatment—for pharmaceutical vials or high-end cosmetic bottles. The goal is usually to improve hydrolytic resistance (preventing alkali leaching) or hydrophobicity (ensuring all liquid drains out, known as "total restitution").

However, clients often mistake these surface treatments for structural reinforcement. It is crucial to understand that a coating is a micron-thin skin. It cannot stop the bulk glass wall from expanding or contracting. The thermal limit is still dictated by the glass substrate (Soda-Lime 1 vs. Borosilicate). The new challenge is ensuring the skin hangs on while the body moves.

If you hot-fill at 90°C or autoclave at 121°C, you are testing the adhesion bond. If that bond breaks, you get flakes in your vaccine or serum—a catastrophic quality failure known as delamination.

Let’s break down which chemistries survive the heat and which ones peel off.

Which internal coating types can tolerate hot-fill, pasteurization, or steam sterilization temperatures?

Selecting the wrong polymer for a hot process ensures failure. You must match the coating’s glass transition temperature 2 (Tg) and thermal stability to your sterilization cycle.

Sol-Gel (Silica-based) and Baked-On Silicone coatings offer the highest heat resistance, easily withstanding autoclaving (121°C) and depyrogenation (>250°C). Standard Epoxies and lower-grade hydrophobic sprays often degrade or yellow above 100°C, making them unsuitable for steam sterilization.

1. Sol-Gel (Silica Nanocoatings)

This is the gold standard for high heat.

-

Chemistry: It is liquid glass ($SiO_2$ network) formed at low temperatures.

-

Heat Limit: > 500°C.

-

Application: It chemically bonds to the glass surface, essentially becoming part of the glass. It is immune to hot-fill and autoclaving. Ideally used to turn Soda-Lime glass into "Type I-like" chemically resistant glass.

2. Medical-Grade Silicone (Baked-On)

Common in pharma vials to prevent protein adsorption.

-

Chemistry: Polydimethylsiloxane 3 (PDMS) emulsion, baked at ~300°C.

-

Heat Limit: Excellent stability up to 300°C.

-

Risk: If not baked properly (fixed), free silicone oil can migrate into the liquid during heating, causing "droplets" in the drug.

3. Ammonium Sulfate (Sulfur Treatment)

Not a coating, but a surface modification.

-

Process: Sulfur gas reacts with surface sodium to form sodium sulfate salts, which are washed away.

-

Heat Limit: Infinite (it modifies the glass itself).

-

Use: The standard method to make soda-lime glass suitable for autoclaved medical saline (Type II Glass).

4. Organic Coatings (Epoxy / Polyurethane)

Rarely used internally due to food safety concerns, but sometimes for decorative effects.

-

Heat Limit: ~80°C – 120°C.

-

Failure: They soften and lose adhesion during pasteurization. Not recommended for hot processes.

| Coating Type | Max Service Temp | Suitable for Autoclave (121°C)? | Suitable for Depyrogenation (250°C)? | Primary Function |

|---|---|---|---|---|

| Sol-Gel ($SiO_2$) | > 500°C | Yes | Yes | Chemical Barrier / Ion Stop |

| Baked Silicone | ~ 300°C | Yes | Yes | Hydrophobicity / Drainability |

| Sulfur Treatment | N/A (Glass) | Yes | Yes | Alkali Neutralization |

| Epoxy / Resin | ~ 100°C | No | No | Chemical Resistance (Cold) |

How can coating thickness and curing conditions change thermal stress behavior and crack risk in glass bottles?

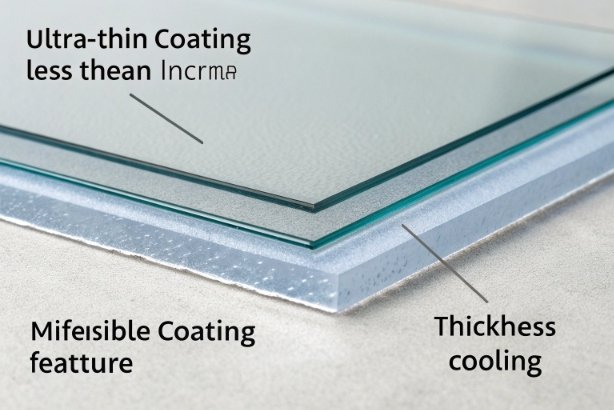

A coating that is too thick acts like a shrinking skin, pulling on the glass surface. Under heat, this tension can rip the coating apart or even craze the glass surface.

Excessive coating thickness (>20 microns) creates a "CTE Mismatch" where the coating expands faster than the glass, leading to shear stress that causes crazing or peeling. Improper curing (under-baking) leaves volatiles trapped; when the bottle is later heated on the filling line, these volatiles explode outward, causing blistering.

The CTE Mismatch Problem

Glass is rigid (CTE ~9.0 x 10⁻⁶/K). Polymers expand 10x to 100x more than glass.

-

Thin Layer (<1 micron): The coating is elastic enough to stretch with the glass. No issue.

-

Thick Layer (>10-20 microns): The coating fights the glass.

Curing: The Hidden Danger

At FuSenglass, we emphasize that curing is not just drying. It is cross-linking 5.

-

Under-Cured: If we bake a silicone coating at 200°C but it needed 300°C, the polymer chains aren’t fully locked. When you later autoclave this bottle at 121°C, the moisture and heat attack the weak bonds. The coating turns "gummy" or white (water blushing).

-

Over-Cured: The coating becomes brittle. Thermal shock causes it to fracture like an eggshell.

What compatibility checks are needed to avoid coating blistering, delamination, or odor migration under heat?

You cannot see a chemical incompatibility until it is too late. Rigorous pre-screening prevents the nightmare of a product recall due to "foreign matter" (coating flakes) in the liquid.

You must check for "Solvent Entrapment" (odor risk), "Hydrolytic Attack" (water undercutting the bond), and "Extractables" (chemical leaching). Heat accelerates all these failure modes, turning minor adhesion issues into total delamination.

1. The "Blister" Mechanism

If the glass surface wasn’t perfectly clean (oil/dust) before coating, the coating bridges over the dirt.

-

Cold: It looks fine.

-

Hot-Fill: The air/moisture trapped in that dirt pocket expands. The coating balloons out and forms a blister. This blister eventually breaks, releasing the dirt into your product.

2. Delamination (The Pharma Killer)

This is specific to Type I and treated Type II glass.

-

Cause: High heat (autoclave) + High pH liquid.

-

Process: The hot liquid eats away the silica under the coating. The coating loses its anchor and flakes off in shimmering sheets (often called "glitter").

-

Check: You must test the coating specifically with your product at your process temperature. Water testing is not enough.

3. Odor Migration

Many organic coatings use solvents. If not fully out-gassed during manufacture:

-

Scenario: You pour hot tea (90°C) into the bottle.

-

Reaction: The heat drives the residual solvent out of the coating and into the tea.

-

Result: A "plastic" taste/smell.

Which validation tests should be used to confirm internal coating stability and heat performance before bulk production?

A datasheet promise is not proof. You must torture-test the coated bottles to simulated extremes to ensure they survive the real world.

Perform the "Autoclave Challenge" (121°C for 60 mins), "Methylene Blue Dye Test" to check for pinholes/continuity after heat, and "Migration Testing" (Odor/Taste) using high-temperature simulants.

1. The Autoclave Challenge

This is the baseline for any heat-resistant coating.

-

Protocol: Fill bottle with water. Seal. Autoclave at 121°C for 1 hour.

-

Pass Criteria:

-

No whitening (blushing).

-

No peeling (tape test).

-

No bubbles.

-

2. Methylene Blue Dye Test

Coatings are transparent; cracks are hard to see.

-

Protocol: After the heat test, fill the bottle with Methylene Blue 6 dye solution.

-

Result: The dye penetrates any micro-cracks or pinholes in the coating, staining the glass blue.

-

Why: It proves the coating barrier is still intact after thermal expansion.

3. Tape Adhesion Test (ASTM D3359)

-

Protocol: Cross-hatch cut the coating (if accessible) or apply vigorous tape to the rim/internal surface.

-

Result: 0% removal allowed.

4. Headspace GC-MS (For Odor)

-

Protocol: Heat the empty coated bottle in a sealed vial to 100°C. Analyze the air (headspace) for solvent peaks.

| Test Name | Purpose | Target Condition | Success Indicator |

|---|---|---|---|

| Autoclave Cycle | Simulate sterilization stress. | 121°C / 60 min | No visual change (haze/peel). |

| Methylene Blue | Detect pinholes/cracks. | Post-Heat Cycle | No blue stain on glass wall. |

| Tape Adhesion | Check bond strength. | Post-Heat Cycle | Coating stays on substrate. |

| Headspace GC | Check for volatile chemicals. | 100°C Heating | No detectable solvent peaks. |

| Coefficient of Friction | Check surface glide. | Pre & Post Heat | Glide remains unchanged (Silicone). |

Conclusion

Internal coatings are a powerful tool for functionality, but they are the "weak link" in thermal processing. To ensure success, stick to Sol-Gel or Baked Silicone for high-heat applications, keep layers ultra-thin (<1 micron), and validate every batch with a rigorous Autoclave Challenge.

Footnotes

-

The most common commercial glass, primarily composed of silica, soda, and lime. ↩

-

The reversible transition in amorphous materials from a hard, brittle state to a viscous state. ↩

-

A silicon-based organic polymer used in a wide variety of applications, including coatings. ↩

-

A network of fine cracks on the surface of a material, often caused by stress. ↩

-

A bond that links one polymer chain to another, affecting physical properties like strength. ↩

-

A chemical compound used as a dye and medication, effective for detecting coating defects. ↩

-

Organic chemicals that have a high vapor pressure at ordinary room temperature. ↩