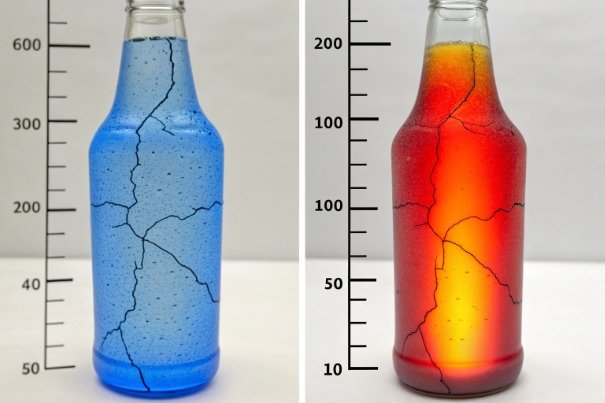

The autoclave is the ultimate stress test for packaging, and without precise control, it turns glass bottles into shrapnel.

Yes, steam sterilization can easily crack glass bottles. The rapid temperature spikes create thermal shock, while the expansion of liquid inside a sealed bottle creates immense internal pressure. If these forces exceed the glass’s tensile strength, the bottle will shatter or the base will separate.

The Dual Threat: Heat and Pressure

At FuSenglass, we advise clients that steam sterilization (autoclaving 1/retorting) is fundamentally different from hot-filling. In hot-filling, you worry about the temperature. In sterilization, you fight a two-front war: Temperature and Pressure.

When you heat a sealed bottle of liquid to 121°C (250°F), water turns to steam. The liquid expands. The headspace 2 gas expands. This creates massive internal pressure (often 1.5 – 2.0 bar).

-

Thermal Shock: If the steam hits a cold bottle too fast, the surface expands while the core is cold. Crack.

-

Pressure Burst: If the internal pressure pushes out harder than the glass can hold (or harder than the external steam pressure pushes in), the bottle explodes.

This process is standard for low-acid foods (soups, dairy, cold brew coffee), but it requires a strictly controlled "Counter-Pressure" cycle.

What cracking mechanisms happen most often during steam sterilization, and how can thermal shock be reduced?

The two main killers in the autoclave are "Thermal Shock Fractures" during the ramp-up/cool-down and "Pressure Breaks" during the hold phase.

Thermal shock occurs when the temperature difference ($\Delta T$) exceeds 42°C, causing surface tension cracks. Pressure breaks occur when internal pressure exceeds the bottle’s burst strength. Risks are reduced by using slow "ramp" rates for heating/cooling and applying "air ballast" (overpressure) to balance internal forces.

Anatomy of an Autoclave Failure

1. Thermal Shock (The Cool-Down Crash):

The most dangerous moment is not heating up; it’s cooling down.

-

Scenario: The cycle ends. The bottles are 121°C. You spray 20°C cooling water. $\Delta T = 100^\circ C$.

-

Result: Immediate catastrophic shattering.

-

Fix: You must cool gradually. 121°C $\to$ 100°C $\to$ 80°C $\to$ 50°C.

2. Pressure Burst (The Cooling Expansion):

-

Scenario: At 121°C, the pressure inside the bottle is high. The autoclave chamber pressure is also high (steam). They balance each other.

-

The Danger: If you vent the autoclave steam too fast, the chamber pressure drops to 0 bar instantly. But the bottle is still hot and pressurized at 2 bar inside.

-

Result: The bottle blows up (or the cap flies off).

-

Fix: Maintain "Overpressure" (pumped air) in the chamber during cooling until the bottles reach < 80°C.

Which glass bottle specs (glass type, wall thickness uniformity, finish design) best withstand autoclave steam cycles?

Not all bottles are "Retort Grade." Using a standard lightweight beverage bottle for sterilization is a gamble.

Type I Borosilicate glass is ideal but expensive. For cost-effective Type III Soda-Lime glass, you must specify "Retort Grade" ware, which features uniform wall thickness (no thin spots), a heavyweight design for pressure resistance, and a "Radiused" finish to prevent thread chipping.

Selecting the Right Vessel

1. Glass Type:

-

Type I (Borosilicate): Can handle $\Delta T$ of 120°C. Virtually immune to autoclave thermal shock 3. Essential for pharma.

-

Type III (Soda-Lime): Can handle $\Delta T$ of only 42°C. Can be used for food sterilization, but requires very slow cycle times.

2. Wall Uniformity (Critical):

In a pressurized environment, a "thin spot" is a blowout point.

-

Standard Bottle: Might vary 1.5mm to 3.0mm.

-

Retort Spec: We aim for strict uniformity. We avoid square shapes (stress concentrators) and prefer cylinders.

3. Headspace Volume:

This is a design spec, not a material one.

- Requirement: You need a larger headspace (10-15%) than for cold fill. The liquid will expand at 121°C. If there is no air gap to compress, the liquid (which is incompressible) will crack the glass hydraulically.

How should sterilization parameters (preheating, ramp rate, pressure balance, cooling curve) be set to minimize breakage?

The autoclave recipe is just as important as the bottle. You must program the machine to respect the physics of the glass.

Minimizing breakage requires a "Ramp Rate" of < 5°C per minute to avoid thermal shock. Crucially, during the cooling phase, the autoclave must maintain "Counter-Pressure" (typically 1.5 – 2.0 bar) to support the bottle walls until the internal liquid temperature drops below the boiling point.

The Safe Cycle Profile

Phase 1: Ramp Up (Heating)

-

Don’t inject full steam instantly.

-

Target: Rise 5°C to 10°C per minute. Allow heat to penetrate the glass wall evenly.

Phase 2: The Hold (Sterilization)

-

Temp: 121°C.

-

Pressure: ~2.1 Bar (Steam).

-

Status: Glass is safe because external pressure equals internal pressure.

Phase 3: The Cooling (The Danger Zone)

-

Action: Steam is turned off. Cooling water is sprayed.

-

Critical Step: Inject Compressed Air (Air Ballast).

-

Why: The cold water drops the chamber pressure. The air ballast artificially keeps the chamber pressure high (e.g., 1.8 bar) to squeeze the bottles.

-

Ramp Down: Cool slowly. Drop temp from 121°C to 40°C over 20-30 minutes.

What supplier QC tests and pilot validation runs can verify steam-sterilization compatibility before mass production?

Lab tests can predict failure, but only a loaded pilot run proves success.

Suppliers must perform "Internal Pressure Resistance" (Burst) tests to ensuring the bottle can handle at least 12-16 bar (for carbonated/retort). Buyers should validate with a "Water Load Pilot," running 50 water-filled bottles through the actual sterilization cycle to check for breakage or seal failure.

Verification Checklist

1. Internal Pressure Test (ASTM C147):

We pressurize the bottle with water until it bursts.

- Retort Standard: Must withstand significantly higher pressure than the expected process pressure (safety factor of 3x). Typical pass > 14 bar (200 psi).

2. Thermal Shock Test (ASTM C149):

Confirm the $\Delta T$ limit. If the bottles fail at $\Delta T$ 42°C, your autoclave cooling ramp must never exceed a 40°C drop in one step.

3. The Pilot Run (The "Dummy" Load):

Never start with your expensive product.

-

Step: Fill bottles with water. Cap them.

-

Run: Execute your proposed 121°C cycle.

-

Inspect:

-

Did any break? (Thermal/Pressure issue).

-

Did caps loose torque? (Liner compression issue).

-

Did bottoms separate? (Thermal gradient issue).

-

Testing Matrix

| Test | Lab / Production | Pass Criteria |

|---|---|---|

| Burst Pressure | Lab | > 200 psi (14 bar). |

| Thermal Shock | Lab | $\Delta T \ge 42^\circ C$. |

| Vertical Load | Lab | > 500N (Seal integrity). |

| Pilot Cycle | Production | 0% Breakage / No Seal Failure. |

Conclusion

Steam sterilization is a violent process for glass. By using uniform, round bottles, maintaining air-ballast counter-pressure, and ramping temperatures slowly, you can sterilize safely without turning your autoclave into a glass grinder.