Manufacturers love sodium because it lowers energy costs, but brand owners should fear it because it compromises product stability. We must understand the trade-off between easy melting and chemical leaching.

Sodium Oxide (Na₂O) acts as a powerful flux that lowers the melting point of glass but significantly weakens the molecular structure. High sodium levels create "Non-Bridging Oxygens" and open pathways for ion migration, directly leading to increased leaching, reduced acid/alkali resistance, and a higher susceptibility to surface weathering.

The Necessary Evil of Sodium in Glass Making

At FuSenglass, we are open about the reality of manufacturing: glass making is a compromise. …Pure silica 1 (SiO₂) is the ideal glass—it is chemically inert and thermally invincible. However, it melts at over 1700°C. To make mass production possible and affordable, we must add a flux to lower that melting point 2 to a manageable 1400°C-1500°C. That flux is Soda Ash [^3] (Sodium Carbonate), which becomes Sodium Oxide (Na₂O) in the glass.

Sodium is the "Soda" in Soda-Lime glass [^4]. While it is essential for the furnace, it is the primary enemy of chemical durability 3. In the glass industry, we refer to glass with high sodium content as "soft" glass—not because it is physically soft, but because it is chemically weak.

When sodium enters the silica network, it doesn’t build bridges; it burns them. It acts as a "Network Modifier" 4. Every sodium atom added breaks a strong Silicon-Oxygen-Silicon bond, creating a gap. These gaps make the glass fluid enough to mold into intricate perfume bottles or beverage containers, but they also leave the structure vulnerable.

From a quality control perspective, managing sodium content is critical. If a batch is mixed with too much soda ash to speed up melting, the resulting bottles may look perfect coming off the line, but they are essentially ticking time bombs for corrosion.

…The Impact of Sodium on Glass Properties

| …Property | Effect of Increasing Na₂O | Manufacturing Benefit | Quality Risk |

|---|---|---|---|

| Melting Temperature | Decreases significantly. | …Lower energy bills; longer furnace life. | …Reduced thermal endurance. … |

| Viscosity | Decreases (makes glass runnier). | Easier to form complex shapes. | …Uneven wall distribution if uncontrolled. |

| Thermal Expansion | Increases drastically. | None. | …High risk of thermal shock breakage. |

| Chemical Durability | Decreases. | None. | High leaching; poor weather resistance. |

| Electrical Conductivity | Increases. | None. | …Poor insulator (not relevant for bottles). |

To protect your product, you need to understand exactly how sodium creates these molecular weaknesses that lead to contamination.

Why do higher Na₂O levels typically increase ion leaching and reduce chemical durability in acidic or alkaline exposure?

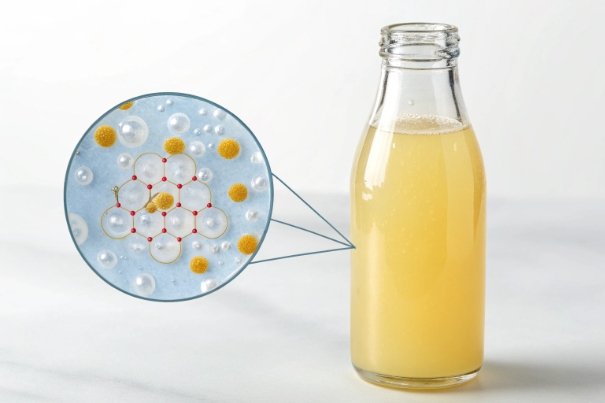

Glass is not a solid wall; it is a stiff liquid full of mobile ions. High sodium content turns the glass surface into a porous membrane that readily exchanges chemicals with your product.

Sodium ions are singly charged and loosely held within the glass network gaps. …When Na₂O levels are high, the network is fragmented by "Non-Bridging Oxygens" (NBOs). This loose structure allows water and acids to easily penetrate the surface and swap Hydrogen ions for Sodium ions, causing rapid leaching and pH shifts in the contained liquid.

The Mechanism of Failure: Ion Exchange

The primary mechanism of glass corrosion in acidic or neutral liquids (like water, juice, or wine) is Ion Exchange.

- The liquid contains Hydrogen ions ($H^+$) or Hydronium ions ($H_3O^+$).

- …The glass contains Sodium ions ($Na^+$).

- …Because Sodium is only loosely trapped in the network voids (unlike Calcium or Silica), it wants to migrate out.

- The $H^+$ moves into the glass to replace the $Na^+$, and the $Na^+$ moves out into your product.

The Multiplier Effect:

The more sodium you have in the glass recipe, the more "lanes" are open on the highway for this exchange.

- Low Sodium Glass: The network is tight. …The "tunnels" are blocked. Migration is slow.

- High Sodium Glass: The network is open. …Sodium floods out.

Alkaline Attack (Dissolution):

In alkaline conditions (high pH), the mechanism is even more destructive. The Hydroxyl ions ($OH^-$) don’t just swap with sodium; they attack the silicon backbone itself. High sodium content weakens the backbone connectivity ($Si-O-Si$ bonds are replaced by $Si-O-Na$). …A network full of $Si-O-Na$ terminals dissolves much faster in caustic soda than a connected silica network. This leads to the glass surface literally shedding layers.

In my experience with pharmaceutical clients, this is the number one cause of recalls related to "glass delamination" 5. The sodium-rich layers hydrate, swell, and then flake off into the drug.

Corrosion Vulnerability by pH

| …Environment | Attack Mechanism | Role of High Na₂O | Result |

|---|---|---|---|

| Acidic (pH < 7) | Leaching. H+ replaces Na+. | Provides the Na+ source for exchange. Creates open diffusion paths. | pH rise in product; potential taste alteration. |

| Neutral (Water) | Hydrolysis. | Na+ dissolves into water, creating NaOH (Alkaline). | Water becomes alkaline (pH spike), attacking the glass further. |

| Alkaline (pH > 9) | Etching. Network dissolution. | Weakens the bond structure, allowing faster breakdown. | …Surface becomes rough, hazy, and thin. … |

| Humid Air | Weathering. | Surface Na+ reacts with air moisture + CO₂. | "Blooming" (White crystals on surface). |

Sodium is dangerous, but we can’t eliminate it. The art of glass making lies in balancing it with other oxides.

How does Na₂O interact with SiO₂, Al₂O₃, and CaO/MgO to balance meltability vs. corrosion resistance?

Glass formulation is a tug-of-war. We need Sodium to melt the sand, but we need Alumina and Calcium to cage the Sodium so it can’t escape.

Sodium acts as the "Accelerator" for melting, while Silica provides the structure, and Calcium/Magnesium act as the "Brakes" on ion mobility. Alumina (Al₂O₃) is the critical mediator; it consumes the Non-Bridging Oxygens created by Sodium, effectively repairing the structural damage and locking the alkali ions into a stable tetrahedral coordination.

The Oxide Ecosystem

At FuSenglass, our batch engineers are constantly tweaking ratios. If we reduce sodium to improve durability, we might have to increase furnace temperature (cost) or add more expensive Lithium (cost). Instead, we use a stabilization strategy.

1. …The Antagonist: Sodium (Na₂O)

-

…Function: Breaks bonds ($Si-O-Si \rightarrow Si-O^-$ $Na^+$).

-

Result: Makes glass meltable but weak.

2. The Stabilizers: Calcium & Magnesium (CaO/MgO) -

…Function: Block the holes.

-

Interaction: The divalent ions 6 ($Ca^{2+}$, $Mg^{2+}$) are chemically stronger and physically larger than Sodium. They sit in the network gaps and physically block the Sodium from moving. …They turn "Soluble Glass" into "Insoluble Glass."

-

Rule of Thumb: We need enough CaO to block the Na₂O, but not so much that the glass devitrifies 7.

3. The Fixer: Alumina (Al₂O₃)

- …This is the most important relationship. When $Al_2O_3$ is added to a high-sodium glass, the Aluminum atom needs a positive charge to balance itself in the network. …It grabs a stray Sodium ion ($Na^+$) to satisfy this charge.

- The Magic: Instead of the Sodium being loose and leachable, it is now electrostatically tied to the Aluminum structure. …The "Non-Bridging Oxygen" is eliminated.

- Optimization: We aim for specific $Al/Na$ ratios to maximize this locking effect without making the glass too viscous.

Formulation Balance Sheet

| …Oxide | Role | Interaction with Sodium | Ideal Strategy |

|---|---|---|---|

| SiO₂ | Backbone | Dissolved by Sodium. | Maximize as much as melting temp allows (~70-74%). |

| Na₂O | Flux | Creates the weakness. | Limit to < 14-15%. |

| CaO/MgO | Stabilizer | Blocks Sodium paths. | Keep CaO+MgO > 10% to "cage" the Sodium. … |

| Al₂O₃ | Intermediate | Binds Sodium tightly. | Add 1.5-2.5% to "heal" the breaks caused by Soda. |

What happens when this balance is wrong? …The risks go far beyond just "bad chemistry." They affect your brand’s visual identity and customer experience.

What real packaging risks can high Na₂O create (surface haze, taste/odor pickup, and coating/print failures)?

A high-sodium bottle is an unstable platform. It actively reacts with its environment, leading to visual defects that ruin shelf appeal and chemical reactions that spoil the product inside.

High sodium content causes "Blooming" (weathering), where alkali salts crystallize on the surface, creating a permanent white haze. Chemically, the leached alkali raises the product pH, causing "off-flavors" or sediment in beverages. Furthermore, the alkaline surface disrupts the adhesion of organic coatings and inks, leading to label peeling and print flaking.

The Trio of Sodium-Induced Failures

1. The "Ghost" Bottle (Weathering/Haze)

Have you ever seen a glass bottle that looks dusty, but when you wipe it, the "dust" doesn’t come off? …That is Weathering, and it is caused by Sodium.

-

…The Science: …In humid storage (like a warehouse in Southeast Asia), moisture condenses on the glass. It pulls Sodium out. The Sodium reacts with $CO_2$ in the air to form Sodium Carbonate ($Na_2CO_3$).

-

The Damage: These crystals etch the glass surface permanently. …Your premium clear vodka bottle now looks like cheap, dirty recycled glass. High Na₂O content accelerates this process exponentially.

2. The Flavor Killer (pH Shift)

For unbuffered liquids (like mineral water, certain spirits, or serums), the glass acts as a chemical reagent. -

The Scenario: …You bottle a pure spring water at pH 7.0.

-

The Failure: …Over 6 months, high sodium leaching releases hydroxide ions ($OH^-$). The pH spikes to 8.5.

-

The Result: …The water tastes "soapy" or "flat." In wine, this can precipitate tartrates. In cosmetics, it can destabilize the active ingredients.

3. The Decor Disaster (Print Adhesion)

Modern packaging relies on organic screen printing 8, UV inks, and polymer coatings.

- …The Conflict: …These organic inks rely on a neutral surface to bond. A high-sodium glass surface is alkaline. This alkalinity attacks the interface between the glass and the ink.

- The Failure: The ink passes the tape test immediately after printing. But after 2 weeks of "alkali bloom" underneath the ink, the print flakes off into the customer’s hand.

Risk Assessment Table

| …Defect | Cause | Indicator | Business Impact |

|---|---|---|---|

| Blooming | Sodium reacting with air/humidity. | White, greasy haze; feels rough. | Loss of premium aesthetic; rejection at filling line. |

| pH Spike | Sodium leaching into liquid. | pH moves from Neutral -> Alkaline. | Taste alteration; product instability; sediment. |

| Print Flaking | Surface alkalinity attacks ink bond. | Ink peels off with tape/friction. | Brand damage; readable regulatory info lost. |

| Delamination | Silica-rich layer separation. | "Glitter" particles in liquid. | Critical Safety Recall (Pharma/Injectables). |

You cannot taste the sodium in the glass, but you can test for it. Here is how to lock down your specifications.

How can B2B buyers specify limits and verify Na₂O-related durability (XRF composition, ISO tests, and lot traceability)?

Don’t rely on the supplier’s promise. Define the chemical boundaries of your packaging in the contract and enforce them with standardized laboratory testing.

Specify a maximum Na₂O content of 15% via XRF analysis to prevent excessive solubility. Mandate ISO 719 (Grains Test) to confirm Hydrolytic Class 3 or better, and use ISO 4802 (Surface Alkalinity) to quantify the actual leaching risk. Always require "Date of Manufacture" traceability to assess weathering risks for older pallet stock.

The Buyer’s Specification Toolkit

As an expert at FuSenglass, I advise global brands to include the following three pillars in their Quality Assurance (QA) agreements.

1. Composition Limits (The Recipe)

Most standard bottles are "Soda-Lime-Silica." But you must define the boundaries.

-

…The Spec: "Sodium Oxide ($Na_2O$) content shall not exceed 14.5%."

-

Verification: Request an XRF (X-Ray Fluorescence) report for each campaign.

-

Why: …If a supplier pushes sodium to 16% to save energy, your durability drops drastically.

2. Hydrolytic Resistance (The Performance)

This measures how much sodium actually comes out. -

…ISO 719 (Grain Test): Measures the durability of the glass material itself.

- Target: …HGB 3 (Standard) or HGB 2 (Treated/Enhanced).

-

ISO 4802 (Surface Test): Measures the durability of the inner surface (critical for the liquid).

- Target: …Specific titration limit (e.g., $< 1.5$ ml of 0.01M HCl per 100ml volume). This is the direct proxy for "how much alkali will enter my product."

3. Inventory Age & Traceability

Sodium leaching is a function of time and humidity. A high-sodium bottle stored for 2 years in a damp warehouse is a disaster.

- The Spec: "Glass pallets must not be older than 6 months at time of delivery."

- The Check: Check the pallet tags and mold dots for production dates. Old glass is "bloomed" glass.

Quality Control Checklist

| …Verification Method | Parameter | Recommended Limit | Purpose |

|---|---|---|---|

| XRF Analysis | Na₂O Content | < 15.0% | Prevent "soft" glass formulation. |

| ISO 719 | Hydrolytic Class | HGB 3 | Confirm basic material standard. |

| ISO 4802 | Surface Alkalinity | Based on Vol. | Protect product pH stability. … |

| Visual Inspection | Haze/Bloom | None | Ensure aesthetic quality. … |

| Traceability | Storage Age | < 6 Months | Minimize weathering risk. |

Conclusion

Sodium is the fuel for glass manufacturing, but it is the poison for glass durability. By understanding its behavior—how it opens the door to leaching and corrosion—and by strictly enforcing composition limits and alkalinity tests, you can ensure your FuSenglass bottles remain a secure vault for your brand’s valuable contents.

Footnotes

-

Fused quartz properties and high melting point of pure silica. ↩

-

Managing viscosity and temperature for efficient glass manufacturing processes.[^3]: Sodium carbonate’s essential role as a flux in glass.[^4]: Composition and characteristics of the most common glass type. ↩

-

Resistance of glass surfaces to weathering and chemical corrosion. ↩

-

How flux ions alter and weaken the silica network. ↩

-

Regulatory risks and causes of glass flaking in drugs. ↩

-

Using calcium and magnesium ions to stabilize glass structure. ↩

-

The prevention of unwanted crystallization during glass manufacturing cooling. ↩

-

Techniques and challenges for printing directly on glass surfaces. ↩