A good sauce in the wrong bottle leaks, clogs, or loses flavor. Then customers blame the product, not the packaging decisions behind it.

You choose the right sauce bottle by matching neck finish and cap to viscosity and chemistry, designing for hot-fill or retort, controlling drips and labeling, and aligning size, color, and coatings with brand and shelf-life needs.

The bottle is part of the recipe. It must work with your filling line, your distribution chain, and how people actually use the sauce at home. I will walk through the choices step by step, from neck finishes to colors.

Which neck finishes and caps suit viscous, acidic, or oily sauces?

The fastest way to ruin user experience is to put a thick sauce in a tiny orifice or a thin sauce behind a huge opening.

Thin sauces need smaller orifices and tight flip or disc tops; thicker sauces need larger openings, yorker or valved caps, and sometimes wide mouths, all matched to the correct neck finish.

Match neck and cap to viscosity and texture

The starting point is viscosity. A watery vinegar-based hot sauce behaves very differently from a sticky BBQ sauce or a chunky salsa.

For thin, free-flow sauces like table vinegar, soy, or classic Louisiana-style hot sauce, a narrow neck and small orifice keep flow under control. Common plastic options are GPI thread-finish standards (e.g., 20/410–28/400) 1. Glass woozy bottles often use small neck finishes with dripper fitment orifice reducers 2. These small inserts give that “dash, not dump” experience.

For medium-viscosity sauces like ketchup, sweet chili, or many dressings, customers expect a squeeze-and-control feeling. Here PET or HDPE squeeze bottles with 24/410 or 28/400 finishes work well, paired with flip-tops or hinged closures. The orifice needs to be wide enough so the sauce flows under gentle squeeze, but not so wide that it floods the plate when the bottle is half-empty.

For thick sauces and pastes, like dense BBQ, tahini, or gochujang, larger orifices and even wide-mouth jars start to make more sense. Yorker spout caps 3, silicone-valved dispensing caps, or simple continuous-thread caps on wide mouths help people scoop or pour without shaking forever. Chunky products with visible pieces often perform best in wide-mouth glass jars, where a spoon or spatula is the primary “dispensing system”.

Oily sauces and infused oils prefer controlled-pour options. Pour spouts, reducer inserts, or specialty oil pourers on standard finishes like 18mm or 31.5mm BVS give a clean, narrow stream and reduce mess on the neck.

| Sauce type | Viscosity / texture | Typical neck finish | Cap / fitment type | Key goal |

|---|---|---|---|---|

| Thin hot sauce | Very thin, no particles | Small finish (e.g. 24/414) | Orifice reducer + screw cap | Dash-style dosing |

| Vinegar / soy | Thin | 20/410–24/410 | Flip-top, disc-top, or controlled pourer | Clean, slow pour |

| Ketchup / mayo | Medium, squeeze-friendly | 24/410–28/400 | Flip-top, valved dispensing cap | No “bottle slap”, easy squeeze |

| Thick BBQ / paste | Very thick | 28/400 and up / wide mouth | Yorker, large orifice flip, or wide-mouth lid | No clogging, allow spoon use |

| Oils / dressings | Thin but oily | Oil-standard or 24/410 | Drip-control pourer, drop insert, or spout | Clean neck, controlled stream |

Handle acidity, salt, and oil chemistry

Neck and cap design also must live with the sauce chemistry. Many sauces are acidic (tomato, vinegar, chili). Others are oil-heavy or salt-loaded. These factors attack different closure materials.

Glass stays inert with acids, salt, and oils, so the main concern is the closure system. For screw caps, the liner material is critical. Acidic sauces often pair well with PVC-free, food-grade liners designed for low migration and good seal. For hot sauces and pickled products, many brands also add a tamper-evident band or shrink sleeve around the cap.

With plastic bottles, resin choice and closure material matter more. HDPE handles acid and salt well and gives good squeeze. PET offers clearer walls and a more rigid feel, but needs careful testing with high-acid recipes over long shelf life. Closures typically use PP, sometimes with TPE or silicone valves. These valves must resist oil swelling and salt, so we run real product contact tests, not only lab simulants.

Oily sauces need special attention at the neck. Oil creeps. If the fit between neck finish and liner is weak, you will see slow weeping around the thread. A well-chosen neck standard, correct torque, and properly matched liner material avoid this. For glass, we often recommend proven closure families used in edible oil; for plastic, we check both seal and stress-crack resistance in contact with oils.

When the product, neck finish, and cap work as one system, the sauce feels easy to use and stays where it belongs: inside the bottle until the customer wants it.

Do hot-fill and retort requirements dictate wall profile and ΔT specs?

Thermal process is not just a food safety topic. It defines what bottle shape and thickness you can safely use without breakage or panel collapse.

Yes, hot-fill and retort conditions drive wall profile, glass ΔT limits, and plastic design. Temperature, pressure, and cooling rate must guide bottle material, thickness, and vacuum panel geometry.

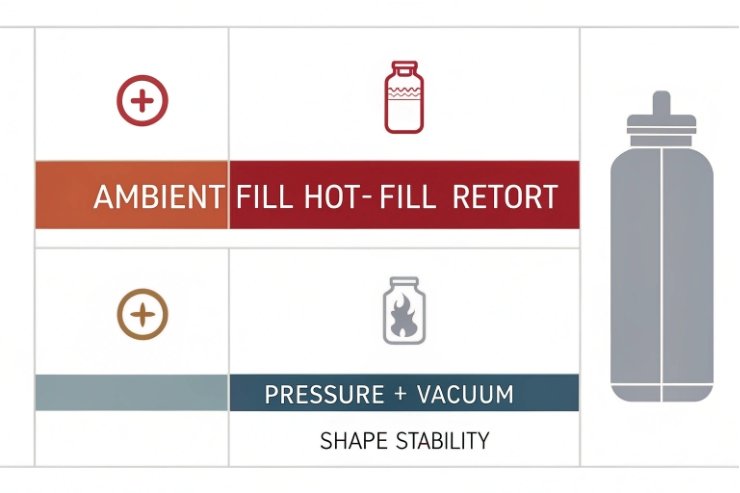

Understand your process: ambient, hot-fill, or retort

The first question is simple: how will you process the sauce?

If you fill at ambient and rely on cold chain, your bottle sees gentle conditions. Standard glass or plastic works as long as the sauce itself does not attack the material.

If you hot-fill, the sauce might enter the bottle at 80–95°C, then invert, then cool. The bottle must survive the filling temperature, the vacuum that forms as the sauce cools, and the thermal shock between hot product and cooler outside air or cooling tunnels. This is why it helps to start with a clear definition of the hot-fill packaging process 4.

If you retort, the package faces even more. It goes into a retort with water or steam at up to 121°C or more, sometimes under pressure, then cools down. Now the package must handle both internal and external pressure, plus large temperature swings—typical of retort processing for shelf-stable sauces (about 116–121°C under pressure) 5.

Each of these steps puts stress on glass and plastic in different ways. That is why we always ask for a full thermal profile: fill temperature, hold time, retort temperature if any, and cooling method. From there we can define the right glass ΔT (maximum safe temperature difference) and the right plastic grade.

What this means for glass bottles

Glass hates sudden temperature shocks. The ΔT spec tells us how much difference between inside and outside temperature the bottle can handle. Higher-quality container glass for hot-fill or pasteurization is designed for higher ΔT, but there is still a limit. A practical way to sanity-check this early is to reference typical thermal shock resistance (ΔT) working ranges for container glass 6.

For hot-filled sauces, we adjust wall thickness and shape. Avoiding sharp corners and extreme embossing helps stress distribution. Strong shoulders and heel curves carry load better. On the body, we sometimes design subtle vacuum panels or ribs that let the bottle flex slightly as internal vacuum builds.

For retort, the design must be even more robust. We use heavier glass, smoother profiles, and tight control on wall distribution. The filling line must respect preheat and cooling rates to stay within ΔT. If cooling water is too cold or sprays hit one side first, cracks appear at the heel or shoulder.

Caps also need to match the process. Metal lug caps with suitable compound liners are common for hot-fill glass jars. They form a vacuum seal as the product cools. For taller sauce bottles, we can use twist-off or crown-style finishes that work in pasteurization tunnels.

What this means for plastic bottles

PET and HDPE behave differently under heat. Standard PET softens at high hot-fill temperatures. So for true hot-fill we use heat-set PET with special mold design and controlled blow conditions. These bottles often show panel designs that can move inward as vacuum forms, instead of pulling the whole wall.

HDPE has a lower heat distortion temperature than glass but can manage many pasteurization or lower hot-fill processes, especially for short cycles. It remains more flexible than PET, which is good for squeeze sauces but less ideal for tall, rigid designs.

Retort in plastic demands special high-temperature polymers or multilayer structures. Many sauce lines avoid full retort with plastic because the cost and complexity rise quickly.

| Process type | Typical temperature range | Preferred materials | Design focus |

|---|---|---|---|

| Ambient fill | 10–30°C | Standard glass, PET, HDPE | Ergonomics, branding, basic strength |

| Hot-fill | 80–95°C | Hot-fill glass, heat-set PET, HDPE | ΔT control, vacuum panels, closure seal |

| Pasteurization | 60–90°C water or tunnel heat | Glass, some PET/HDPE | Wall strength, closure compatibility |

| Retort (up to 121°C) | 100–121°C plus pressure | Heavy glass, specialty plastics | High ΔT, pressure resistance, shape stability |

Once the process is clear, we can design the bottle so it survives not just the first run, but every production day with consistent safety margins.

What drip-control fitments and label panels improve usability?

Customers judge a sauce bottle in the first seconds: does it drip, clog, or mess up the table? And can they read the label after the bottle sits in a wet fridge door?

Drip-control fitments, flow restrictors, and well-planned label panels make sauces easier to pour, cleaner to use, and clearer to shop and scan.

Control the pour and keep the neck clean

Drip control starts at the orifice. For thin sauces, simple open finishes often give too much flow and leave streaks on the neck. Orifice reducers, drop inserts, and narrow spouts fix this. They reduce the flow area and shape the stream, so each shake or tilt releases a small, repeatable dose.

Flip-top caps with integrated pour spouts work well on plastic squeeze bottles. Some include silicone valves that open under pressure and close when the squeeze stops. This design keeps the product from “sucking back” air and reduces dried sauce on the tip. It also keeps the bottle cleaner when it is upside down in the fridge.

For thick sauces, anti-clog is more important than drip control. Larger orifices, smooth internal channels, and short flow paths help. Some yorker caps have cuttable tips; the customer can trim the opening to fit the sauce thickness. This keeps flexibility across small changes in recipe or temperature.

Glass bottles often use press-in reducers or droppers under a screw cap. This is common for hot sauces and strong condiments. The reducer regulates flow and keeps the cap thread clean. When we design glass finishes for these markets, we make sure the bore diameter and tolerances accept standard reducer inserts without leaks.

| Use case | Fitment / closure | Main benefit |

|---|---|---|

| Thin chili sauce | Orifice reducer + screw cap | Controlled dashes, clean neck |

| Squeeze ketchup | Flip-top with valve | One-hand use, no “glug”, reduced mess |

| Oil-based dressing | Controlled pour spout | Narrow stream, less overpour |

| Chunky salsa | Wide-mouth lid | Spoon or chip access, no clogging |

| Cooking glaze | Yorker cap | Fine lines for basting and plating |

Design label panels that work in real life

A beautiful label that wrinkles, peels, or becomes unreadable under condensation does not help sales. Sauce bottles often live in chilled, wet environments. That means we need both good label material and smart bottle geometry—often including shrink sleeves for refrigerated products with condensation 7.

Flat or gently curved label panels give printers and applicators a stable surface. Deep curves, ribs, or heavy embossing under key information areas make labels harder to apply and easier to wrinkle. When we design glass or plastic sauce bottles, we reserve at least one “quiet” panel for the main label and one smaller space for a back or side label.

Cold-chain products face condensation. Smooth, low-texture surfaces help labels stick even when the bottle goes from hot fill to cool water to cold shelf. Some clients choose coated glass that improves label adhesion, especially for paper labels in premium ranges.

Regulatory text, ingredients, and barcodes need enough height and width. A tiny label on a tall, round bottle can force very small fonts. So we check early how much text must fit, then size the panel accordingly. A clear, well-placed barcode reduces scanning problems at checkout and helps logistics.

We also think about how people hold the bottle. Grip zones should not sit on top of delicate metallized labels. A gentle waist, shoulder grip, or subtle paneling can guide the hand without stealing space from branding. This is where shape, label area, and closure style all meet to create a simple “pick up, read, pour” experience.

Which sizes, colors, and coatings support branding and shelf life?

After function and safety, size and color decide how the sauce feels on the shelf and at the table.

Bottle size shapes usage and price perception; color and coatings protect light-sensitive sauces and translate your brand story into glass or plastic.

Choose sizes that fit consumption and margin

Size planning is not only about fill volume. It affects shipping cost, retail price, and how fast the product moves at home.

For hot sauces, the classic 5 oz (about 150 ml) “woozy” bottle became a standard because it balances trial and flavor intensity. It is big enough to last, yet small enough that adventurous buyers will try new flavors. Larger 8–10 oz formats suit mainstream or high-rotation sauces where people pour freely.

Family table sauces like ketchup, mayo, and BBQ usually sit in 300–1000 ml ranges. Smaller sizes suit café tables and foodservice portion control. Bigger sizes suit grocery retail for families. Squeeze bottles with inverted caps work well in these ranges because they keep product ready to pour and minimize trapped leftovers.

For premium or very expensive ingredients, such as truffle sauces or specialty oils, smaller glass bottles support a higher price per liter without scaring the shopper. Heavy glass and precise closures help here, since the customer expects a gift-like feel.

Case pack and palletization also matter. Tall, narrow necks look elegant but can reduce case stability. Oval or rectangular cross-sections pack more densely and use shelf space better. When clients want both e-commerce efficiency and retail presence, we often suggest compact cross-sections with enough front label area.

Use color and coatings to protect and position

Light-sensitive sauces need more than a nice label. Herb-based sauces, oil-rich dressings, and some chili products can oxidize or lose color under light. For these, amber or dark green glass gives extra UV protection. In plastic, tinted PET with UV absorbers helps, though protection may fade over time.

Clear glass or PET works well when the sauce color is a key part of the appeal and the formula is relatively stable. Bright red pasta sauce or golden sweet chili looks great in clear containers, especially under store lighting. If shelf life and storage conditions are good, the marketing benefit of visible product can outweigh the modest light risk.

Coatings add another layer of control. A full-body spray coating on glass can block light while still carrying vivid brand colors. Frosted or matte coatings give a natural, craft feel and hide minor product staining inside the wall. They also increase label contrast.

For sustainability-focused brands, natural greens and amber tones hint at eco-conscious positioning. For bold, modern brands, solid black or white bottles with strong graphics stand out. The trick is not to forget function while chasing aesthetics. A pure black, glossy coating looks great, but must still be food-safe, resistant to washing, and compatible with recycling rules in target markets.

| Product type | Light sensitivity | Color / coating choice | Branding effect |

|---|---|---|---|

| Vinegar-based hot sauce | Medium | Clear or light flint, cartons for export | Shows color, “craft” appearance |

| Herb / pesto sauce | High | Amber or dark green glass | Natural, protective, “authentic” |

| Oil-rich dressing | High | Tinted or coated glass, UV additives | Premium, helps prevent color loss |

| Everyday ketchup / mayo | Low to medium | Clear PET or light-tint squeeze bottle | Familiar, family-friendly |

| Gourmet limited release | Medium | Heavy flint with partial coating | Luxury, gifting, high price acceptance |

When size, color, and coating work together with the right neck and cap, the bottle becomes a silent salesperson. It protects the sauce, supports shelf life, and tells the brand story from the first glance.

Conclusion

The right sauce bottle is a system: material, neck, closure, shape, and color all must match your recipe, process, and how customers actually eat and store the product.

Footnotes

-

Quick guide to common thread finishes so caps, reducers, and pumps actually fit. ↩︎ ↩

-

Shows real-world dripper/orifice reducers used for hot sauce and thin condiments. ↩︎ ↩

-

Explains yorker caps and why they’re popular for clean, targeted dispensing. ↩︎ ↩

-

Practical overview of hot-fill steps and packaging choices that prevent paneling, leaks, and quality loss. ↩︎ ↩

-

Clear explanation of retort conditions for shelf-stable sauces and why packaging must handle heat and pressure. ↩︎ ↩

-

Useful ΔT reference ranges to avoid thermal-shock cracks when moving from hot fill to cooling. ↩︎ ↩

-

Helps choose label technology that survives cold-chain handling, wet shelves, and condensation. ↩︎ ↩