Glass water bottles look simple, but behind every “safe” bottle there is a long list of tests, tolerances, and documents most consumers never see.

To ensure glass water bottles meet industry standards, you combine mechanical tests (impact, pressure, thermal-shock), tight neck-finish tolerances, food-contact–compliant materials and coatings, and a documented QA system with AQL sampling, COAs, and full batch traceability.

If even one part fails—wrong coating, poor finish, missing migration report—you carry the liability, not the glass plant. That is why I like to treat bottles, closures, inks, and paperwork as one “system” and qualify everything together before trusting it with a premium water brand.

Which performance tests prove a glass water bottle is “fit for use”?

Most failures show up as cracks, chips, or sudden breaks, so the first job is to prove the bottle can survive real-world abuse before it goes anywhere near customers.

At a minimum, I expect impact/drop, internal pressure, vertical load, thermal-shock, and residual-stress checks, run to recognized ASTM/ISO methods and tied to clear pass/fail limits in the bottle specification.

Impact and drop testing

Impact and drop tests simulate what actually happens in warehouses, on filling lines, and in consumer hands. Typical checks include:

- Single-bottle impact tests (pendulum or striker) onto the sidewall and heel.

- Filled-bottle drop tests from realistic heights (table height, waist height).

- Case drop tests (for shipping systems) on flat, edge, and corner orientations.

You define:

- Drop heights by market (for water, 0.8–1.2 m is common for consumer-level events).

- Orientations (base-first, side, shoulder, corner of case).

- Pass criteria (no breakage, no cracks, no cap loss, no leaks).

The goal is not to make glass unbreakable, but to make sure normal shocks do not routinely create breakage or microcracks that fail later during transport.

Internal pressure and vertical load

Even for still water, internal pressure is not always “zero”. Carbonated waters, flavored waters, and temperature changes can generate significant internal load. So I always want:

- Internal pressure / burst test to a defined pressure above worst-case conditions.

- Vertical load (top-load) test to make sure stacked pallets do not crush the base or finish.

Conceptually:

| Test | What it simulates | Why it matters |

|---|---|---|

| Internal pressure (burst) | Carbonation, temperature swings, misuse (e.g., left in hot car) | Stops spontaneous breaks and leaks |

| Vertical load | Stacked cases on pallets, warehousing | Prevents base and heel failures |

When you need a single reference point for the burst method and reporting, many specs cite ISO 7458:2004 internal pressure resistance test methods 1.

For top-load acceptance criteria and test setup, ISO 8113:2004 resistance to vertical load test method 2 is commonly used.

Thermal-shock (ΔT) resistance

Consumer water bottles see temperature swings when someone fills them with hot water, washes them, or moves them from hot to cold environments. Thermal-shock tests check that the bottle can handle the expected ΔT:

- Hot water fill followed by cooler ambient air.

- Cold storage followed by a warm rinse.

- Dishwashing or sterilization where applicable.

Typical lab methods place bottles in hot water, then cold water (or reverse) with a controlled temperature jump. You then define:

- A target ΔT that reflects your worst realistic scenario plus a safety margin.

- Pass conditions (no cracking, no visible damage, no hidden cracks under polariscopic exam).

For defining thermal-shock resistance and endurance in glass containers, ISO 7459:2004 thermal shock resistance and thermal shock endurance test methods 3 is a practical baseline.

For reusable water bottles, I like to be more conservative, because consumers are creative. If you plan to market bottles as “dishwasher safe” or “for tea and hot water”, the ΔT spec and testing must match those claims.

What dimensional and finish tolerances keep caps leak-free?

Most “quality issues” for water bottles are not glass breaks; they are slow leaks, dribbles in bags, or caps that feel inconsistent. These nearly always trace back to neck-finish tolerances.

Leak-free caps depend on tight control of neck-finish dimensions (thread, height, sealing land, ovality, tilt) within GPI/ISO tolerance tables, plus a body that runs straight enough for consistent capping torque.

Critical neck-finish dimensions

Every closure system—PP screw, steel ROPP, sports cap—assumes certain glass dimensions. At a minimum, I watch:

- Finish outer diameter and ovality (too big, too small, or too oval creates seal issues).

- Thread profile (pitch, depth, start angle) so the cap runs down smoothly.

- Sealing land width and flatness for liners that need a clean contact ring.

- Finish height relative to the support ring and shoulder for correct cap travel.

- Finish tilt / perpendicularity so the cap sits square and seals evenly.

A simple mapping:

| Parameter | Why it matters |

|---|---|

| T, E diameters | Cap thread engagement, torque consistency |

| H height | Cap travel and tamper-band activation |

| Sealing land width/flatness | Gasket compression and leak prevention |

| Ovality / out-of-round | Prevents gaps in the seal line |

| Finish tilt | Avoids “high side” leaks and wobbly caps |

I always insist that suppliers share their finish drawings with tolerances clearly marked and aligned with GPI or ISO neck-finish standards. Then your closure vendor can check compatibility on paper before you even cut molds.

Body and base tolerances

Even if the neck is perfect, a bottle with high lean or ovality can cause:

- Cross-threading or cocked caps in the capper.

- Uneven torque, with some bottles too tight and others too loose.

- Poor performance on sports caps or flip-tops.

Key body tolerances include:

- Overall height and straightness.

- Body diameter and ovality.

- Lean and verticality (how far the bottle leans from center).

- Base stability (rocking, high points on the base ring).

If your line is fast (or your caps are sensitive), it helps to define verticality with a recognized method like ISO 9008:1991 glass bottles verticality test method 4.

How to verify dimensions at incoming inspection

On the buyer side, I like a simple three-layer approach:

-

Dimensional checks

- Use gauges or CMM/optical devices on a defined sample size per batch.

- Confirm neck dimensions, ovality, and critical body dimensions against spec.

-

Cap fit and torque tests

- Apply your actual caps with your torque settings to sample bottles.

- Check opening torque, reseal performance, and leaks after storage at different temperatures (e.g., ambient, 40°C, chilled).

-

Visual finish inspection

- Look for chips, checks, rough sealing surfaces, and heavy mold seams.

- Disposition any lot that shows systemic finish defects.

This combined approach protects you much more than a simple “weight and height” check.

Which glass, coatings, and accessories are safe for food contact and migration?

“Food grade” is not a magic phrase. Every material touching water—glass, coatings, inks, caps, liners—must meet specific food-contact and migration requirements in your target markets.

For glass water bottles, you want soda-lime glass, compliant hot-end/cold-end coatings, and certified closures, inks, and sleeves that pass food-contact and migration checks under FDA, EU, or national FCM rules.

A good starting point for Europe is the EU Regulation (EC) No 1935/2004 framework for food contact materials 5. For the U.S., a practical closure example many teams reference is 21 CFR 177.1210 closures with sealing gaskets for food containers 6.

Glass composition and heavy metals

Water bottles are almost always made from soda–lime–silica glass. To qualify them as food-contact safe, suppliers should show that:

- Raw materials and colorants are free from restricted heavy metals (e.g., lead, cadmium).

- Overall and specific migration from the glass meets applicable limits (EU 1935/2004 framework, national standards, or FDA criteria).

- Any colorants (for tinted glass) are permitted for contact with beverages.

For many jurisdictions, glass as a material is broadly accepted, but you still want documented test results and declarations, not only verbal assurances.

Coatings, inks, and decorative layers

Glass bottles almost always have:

- Hot-end coating (often tin oxide) to improve scratch resistance.

- Cold-end coating (often a polyethylene or similar layer) to lower friction.

- Optional ceramic inks, organic inks, or coatings for decoration.

All of these layers sit between the environment and the consumer. While they usually do not touch the water directly, they still count as food-contact relevant. I like to see:

- Confirmation that hot and cold coatings comply with food-contact rules.

- Migration testing when decoration covers large surface areas or includes metals/pigments (e.g., gold, silver, strong colors).

- Clear statements that inks and coatings are free from substances of concern under your chosen regulatory regime.

If you plan to have full-body shrink sleeves or pressure-sensitive labels, remember that any adhesive or varnish that can reach the mouth-contact area also needs evaluation.

Closures, liners, and accessories

From a regulatory point of view, the “packaging system” includes:

- Cap shells (metal or plastic).

- Liners and gaskets.

- Sports caps, drinking nozzles, silicone rings.

- Any protective or decorative silicone sleeves that may touch lips.

Each of these must:

- Use materials listed or cleared under the relevant food-contact framework (e.g., 21 CFR for the U.S., specific EU FCM measures, GB standards for China, etc.).

- Pass migration testing in contact with water and other relevant simulants (for example, if you may also fill flavored or acidic waters).

- Be evaluated as a full system wherever possible, not just as individual parts.

For premium water brands, I also pay attention to microplastic sources in cap linings and lacquers. Selecting well-qualified cap suppliers and controlling cleaning and handling is part of the same safety story.

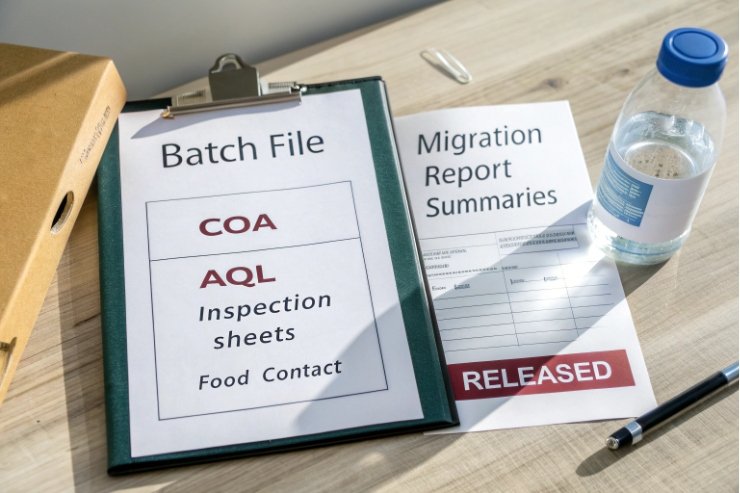

What documentation and QA systems should bottle suppliers provide?

Even the best glass is incomplete without paperwork. When something goes wrong, the documents prove you did your due diligence and let you trace issues to specific lots and molds.

A robust supplier should provide clear specifications, COAs per batch, AQL-based inspection data, food-contact Declarations of Compliance, migration test reports, and full traceability records linked to mold, furnace, and date codes.

Batch-level quality documents

For every delivery, I expect at least:

-

Certificate of Analysis (COA) for the production batch, listing:

- Key dimensions and tolerances checked.

- Mechanical test results (e.g., pressure, vertical load, ΔT).

- Visual defect levels and categories.

-

AQL inspection records detailing:

- Sampling plan (e.g., lot size, sample size, inspection level).

- Acceptable Quality Levels by defect class (critical, major, minor).

- Actual counts and decision (accept / reject).

If you want one widely used acceptance-sampling reference to align supplier and buyer expectations, use the ANSI/ASQ Z1.4 acceptance sampling standard 7.

These documents prove that the supplier monitors quality, not just produces glass and ships it.

Compliance files and certifications

On top of batch documents, you need a compliance “package” for your files, including:

- Declarations of Compliance (DoC) for food contact, referencing specific regulations (e.g., FDA, EU 1935/2004, local rules).

- Migration test reports for glass, coatings, and decorations, ideally following glass-specific FCM guidelines.

- GMP and HACCP documentation showing how the plant controls contamination, glass fragments, and hygiene.

- Plant certifications such as ISO 9001 (quality), ISO 22000 / FSSC 22000 / BRCGS / SQF Packaging for food safety and packaging GMP.

This set lets you satisfy auditors, brand-owner requirements, and retailer technical teams without scrambling for proof.

Traceability and change-control

True control means you can link a problem bottle back to a specific furnace, time window, and mold set. So I always check that suppliers:

- Mark bottles with mold codes and production date or batch codes.

- Maintain records that connect those codes to raw materials, process conditions, and test results.

- Have a formal change-control process, where any change in glass batch, coating chemistry, decoration, or process is:

- Assessed for impact on food contact and mechanical strength.

- Communicated to customers in advance.

- Revalidated with updated test data where needed.

On your side, you should mirror this by:

- Recording which bottle batches go into which finished product batches.

- Keeping QA data and COAs attached to each filling lot.

- Defining your own AQLs and test plans for incoming glass.

When this loop is closed, you are not only meeting “industry standards”. You are building a system that can detect and correct issues early, protect your brand, and prove due care if anything is questioned later.

Conclusion

Glass water bottles only truly meet industry standards when design, testing, food-contact compliance, and documentation all line up, so every bottle is strong, safe, and fully traceable from furnace to consumer.

Footnotes

-

ISO baseline for glass internal-pressure/burst testing and reporting.

https://www.iso.org/standard/35606.html↩︎ ↩ -

ISO method for verifying top-load/vertical-load resistance of glass containers.

https://www.iso.org/standard/35617.html↩︎ ↩ -

ISO test methods for thermal-shock resistance and endurance in glass containers.

https://www.iso.org/standard/35615.html↩︎ ↩ -

ISO method to measure bottle verticality, helping prevent capping and filling-line issues.

https://www.iso.org/standard/16550.html↩︎ ↩ -

EU framework explaining general safety and compliance principles for food contact materials.

https://food.ec.europa.eu/food-safety/chemical-safety/food-contact-materials_en↩︎ ↩ -

FDA eCFR rule example for closure gasket materials used on food containers.

https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-177/subpart-B/section-177.1210↩︎ ↩ -

Official ASQ page describing ANSI/ASQ Z1.4 AQL sampling plans and switching rules.

https://asq.org/quality-resources/z14-z19↩︎ ↩