Honey producers often ask one question: glass jar or plastic bottle? The choice looks simple, but it changes flavor, shelf life, and how customers see the brand.

Storing honey in glass jars is preferable because glass is non-reactive, airtight, and a strong barrier to moisture, oxygen, and odors. It protects aroma, color, enzymes, and texture for many years, tolerates gentle heating, and supports a premium, sustainable brand image better than most plastics.

When honey goes into the wrong container, it slowly loses aroma, darkens faster, or even picks up plastic notes. When it goes into the right glass jar with the right closure, it can sit for years in a pantry and still taste like it was packed yesterday. The rest of this article looks at why glass works better, how it compares to PET and PP, and how to choose jars, lids, and sizes that make honey easier to pour, scoop, and display.

Does glass better preserve aroma, color, and enzymes over time?

Honey is sensitive. It looks stable, but its aroma, color, and enzymes react to light, heat, oxygen, and moisture. The container material decides how fast these changes happen.

Glass preserves honey’s aroma, color, and enzymes better than plastic because it is non-reactive, non-porous, and almost impermeable to moisture and oxygen. Amber glass also blocks light, which slows color darkening and protects bioactive compounds and enzymes during long-term storage.

What is happening inside a jar of honey?

Honey is a concentrated solution of sugars with organic acids, minerals, and enzymes such as diastase, invertase, and glucose oxidase 1. Many producers also align with quality expectations described in the Codex Standard for Honey (CXS 12-1981) 2. Over time, high temperature, excess oxygen, and light can break these enzymes down and change color from light gold to darker amber.

When honey sits in glass, it touches a hard, inert surface. Glass is nonporous and impermeable 3—it does not react with the natural acidity of honey, and it does not absorb water or aroma molecules. So the only real enemies are environment and handling: storage temperature, light levels, and how tight the closure is.

How glass compares with plastic on barrier performance

PET and PP are good packaging materials for many products. However, they are still polymers with small but measurable permeability to gases and moisture. Honey is hygroscopic, so even a small moisture ingress over months can change water activity and texture.

Here is a simple comparison:

| Property | Glass jar | PET bottle | PP container |

|---|---|---|---|

| Moisture barrier | Excellent (practically 0) | Good but not perfect | Moderate |

| Oxygen barrier | Excellent | Moderate to good | Moderate |

| Odor absorption | None | Possible over time | More likely than PET |

| Reaction with honey acidity | None | Possible very slight over time | Slight risk over long storage |

With glass, the honey environment stays stable. With plastic, the small, constant exchange with the outside world slowly nudges quality downward, especially when storage time is counted in years, not weeks.

Role of light and temperature in aroma and color

Light and heat speed up the chemical reactions inside honey. This affects aroma compounds first, then color and enzymes. Dark or amber glass acts like built-in sunglasses. It cuts UV and part of visible light, so sensitive components break down more slowly.

Gentle decrystallization is another point. Honey crystallizes naturally. Many brands warm jars in a water bath to bring honey back to a smooth, liquid state. Glass handles this mild heating very well without shape change or release of additives. Many plastics start to soften, warp, or release additives long before glass shows any problem. If you want a simple technical marker for “overheating or aging,” research on 5-Hydroxymethylfurfural (HMF) levels in honey 4 is a useful reference point. So glass not only protects honey during storage but also during the inevitable “rescue” from crystallization.

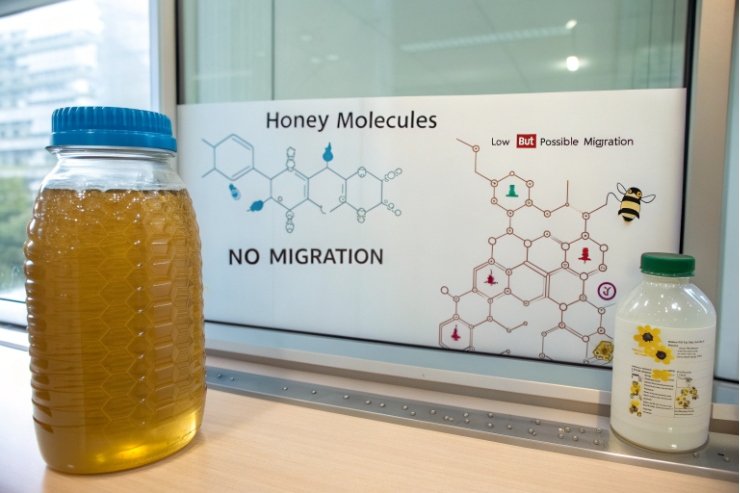

How do migration and odor transfer risks compare between PET/PP and glass?

During long storage, there are two hidden risks: small molecules migrating from packaging into honey, and foreign odors going through the packaging wall into the product.

Glass has essentially zero migration and very low odor transfer, while PET and PP can slowly release or absorb small molecules over time, especially under heat. For multi-year honey storage and premium positioning, glass offers the safest, cleanest contact surface.

What is migration in food packaging?

Migration is the movement of small molecules from the packaging into the food. In plastics, these can be:

- Residual monomers

- Plasticizers and stabilizers

- Colorants or slip agents

Regulations set limits, and reputable suppliers stay within them. However, honey is often stored for years, sometimes in warm rooms or bright kitchens. Time and temperature increase migration risk. Honey’s acidity and high sugar content can also interact with some additives.

In the EU, general rules for Regulation (EC) No 1935/2004 on materials intended to come into contact with food 5 set the baseline expectations for safety and inertness. Risk assessors also focus on how food contact materials can transfer chemicals into food 6 under realistic conditions.

Glass is a network of silica and metal oxides. Its surface is stable and non-reactive. There are no plasticizers to move, no organic additives to leach, and no pores to hold residue. This is why glass is the preferred choice wherever brands promise “no migration” and “clean label” contact.

Odor and flavor transfer from and into packaging

Plastics can both release and absorb odors. A new plastic container sometimes has a light “plastic smell.” It is harmless at normal levels, but sensitive noses can pick it up when honey is delicate and floral. Over time, the polymer wall can also absorb aroma compounds from the honey itself, dulling the product’s character and leaving less aroma in the headspace when the lid opens.

Odors can also move in the other direction. If cartons of plastic-packed honey sit near strong-smelling products, the plastic wall is not a perfect barrier. Spices, cleaning agents, or perfumes nearby can leave a trace inside. With glass, the wall is rigid and non-porous, so outside smells stay outside. This is important in mixed warehouses or small shops.

Microplastics, scratching, and long-term stability

Plastic surfaces can scratch during transport or handling. Tiny particles may detach, especially if the container is squeezed or dropped. Over very long storage, especially at high temperatures, there is also gradual aging of the polymer itself. Broader reviews like Food Packaging and Chemical Migration 7 explain why time, heat, and contact conditions matter more as storage gets longer. Honey packed in glass avoids these microplastic concerns almost entirely.

A simple view:

| Risk / Issue | Glass | PET / PP |

|---|---|---|

| Chemical migration | Negligible | Low but not zero |

| Odor from packaging | None | Possible “plastic” note |

| Odor pickup from outside | Very low | Higher, especially long term |

| Microplastic concern | No | Possible over long time and abuse |

| Surface scratching | Hard and stable | Easier to scratch |

For everyday table honey with quick turnover, PET or PP may be acceptable. For raw, premium or export honey that needs to sit years and answer strict audits, glass is the safer and more convincing answer.

Which closures and liners keep honey airtight without crystallization issues?

The jar material is only half the story. The closure system decides how airtight the package is and how stable the headspace stays during storage and transport.

For glass honey jars, metal lug or twist-off caps with quality plastisol or PVC-free liners give the most reliable hermetic seal. PP screw caps with good liners or swing-top caps with silicone gaskets also work well, as long as they keep moisture out and survive mild decrystallization heat.

What does honey really need from a closure?

Honey needs:

- Airtight sealing against moisture and airborne yeast

- Good oxygen barrier

- Compatibility with honey acidity

- Stable performance when the jar is warmed for decrystallization

Crystallization itself is a natural process driven by sugar ratio, temperature, and seed crystals. The closure does not cause crystallization, but a poor seal can let in moisture. This can change water activity and texture, and in some cases increase fermentation risk.

Comparison of common closures for glass honey jars

| Closure type | Typical liner | Pros | Points to watch |

|---|---|---|---|

| Lug / twist-off metal cap | Plastisol / PVC-free | Strong vacuum seal, great barrier | Needs correct torque and headspace |

| Continuous thread metal cap | Plastisol / PVC-free | Classic look, reliable, good barrier | Works best with compatible neck finish |

| PP screw cap for glass | PE / EVA liner | Light, easy to open, no rust | Slightly weaker gas barrier than metal |

| Swing-top with wire bail | Silicone gasket | Reusable, “craft” look | Needs gasket quality and maintenance |

Metal caps with plastisol liners are standard for many honey brands. When used with hot-fill or warm-fill, the cooling product creates a vacuum that pulls the liner tight against the glass finish. This gives a strong hermetic seal and a clear “button” signal for the consumer.

Closures and decrystallization

When customers decrystallize honey at home, they often place the whole glass jar in a warm water bath. A good closure must tolerate this without:

- Warping

- Losing torque

- Allowing water to leak inside

Metal caps handle this well as long as the water is not boiling. PP closures can also work, but they need heat-resistant liners and controlled temperature. Swing-top closures with silicone gaskets give excellent reusability and can be a good choice for local or refill concepts.

To avoid crystallization problems at the closure area, manufacturers should:

- Fill at the right temperature

- Avoid honey residue on the jar finish before capping

- Set proper torque so the cap is tight but not over-tight

The real control of crystallization still comes from honey composition and storage temperature, while the closure protects against moisture swings and contamination.

What jar shapes and capacities optimize pouring, scooping, and shelf display?

Shape and size influence how people use honey every day and how the brand appears on the shelf. The same honey can feel “cheap” or “premium” only because of the jar choice.

For liquid honey, medium-height jars with narrower mouths pour cleanly and reduce dripping. For creamed or thick honey, wide-mouth jars make scooping easy. Popular capacities like 250 g, 500 g, and 1 kg balance consumer convenience, shipping efficiency, and shelf presence.

Matching jar shape to honey style and use

Different honey types and sales channels need different shapes:

| Honey type / use | Recommended jar shape | Mouth style |

|---|---|---|

| Runny table honey | Round or hex, medium height | Standard / small CT |

| Premium single-origin honey | Custom, faceted, or heavy-base round | Standard CT |

| Creamed or whipped honey | Wide-mouth round or low square | Wide CT / lug |

| Foodservice / bakery use | Large wide-mouth jars or glass tubs | Wide CT / lug |

Runny honey pours more cleanly from a narrower opening. Thick honey needs spoon access, so wide-mouth designs reduce frustration. For gift sets and premium segments, unique shapes and heavier bases create a more luxurious hand feel and justify higher price points.

Capacities that work for home and export markets

Common sizes that work well in glass:

- 250 g (about 8 oz): good for gift packs, tasting sets, and premium lines

- 500 g (about 16 oz): most popular family size in many markets

- 1 kg (about 32 oz): value size for heavy users or foodservice

Larger containers, like 2–3 kg wide-mouth glass jars, suit bakeries, cafes, or horeca clients who want quality and a reusable container.

For logistics, square or hex jars often pack more tightly in cartons, improving pallet efficiency. Round jars run smoothly on filling lines and work with standard neck finishes and closures.

Ergonomics and label space

People judge a jar not just by looks but by how it feels in the hand and how easy it is to empty. Good honey jars often have:

- A clear “grip” zone without sharp edges

- Gently sloped shoulders that guide product flow

- A mouth wide enough for common spoons or mini spatulas

From a branding point of view, flat panels on hexagonal or square jars give clear label space. This helps show origin, floral source, certifications, and story without wrapping text onto a curve. For export markets with many languages, extra label space is especially helpful.

A simple design rule works well: let the jar shape echo the idea of honey itself. Hexagonal jars suggest honeycomb, round jars suggest drops or pools of honey, and heavy bases suggest richness. When this shape is combined with the technical advantages of glass, the result is packaging that supports both daily use and long-term product stability.

Conclusion

Glass honey jars, combined with well-chosen closures and smart shapes, protect aroma, color, and enzymes better than plastic, while also lifting brand image and making honey easier to use and display.

Footnotes

-

Research review explaining key honey enzymes and how storage affects them. ↩ ↩

-

Official Codex PDF defining honey composition and quality requirements used in trade standards. ↩ ↩

-

Why glass’s nonporous, inert surface helps preserve flavor and avoid interactions with packaged foods. ↩ ↩

-

Review on HMF formation in honey and why overheating or poor storage accelerates quality loss. ↩ ↩

-

EU framework regulation text for food-contact materials, useful for compliance language and audits. ↩ ↩

-

EFSA overview of chemical migration from packaging and how safety assessments are performed. ↩ ↩

-

Scientific review of packaging chemical migration drivers like time, temperature, and food composition. ↩ ↩